PROFACTOR 3/4" PF FS 238.20 Технический паспорт онлайн [10/18] 867271

10

Profactor Armaturen GmbH

Adolf-Kolping-Str. 16, 80336 München, Germany, Telefon: +49 89 21546092

E-mail: info@pf-armaturen.de, Internet: www.profactor.de

7. OPERATION AND MAINTENANCE INDICATIONS

The filter should not be exposed to direct sunlight, UV radiation, heat sources above 65°С,

solvent vapors, oils, alkaline washing solutions, any chemical substances.

Avoid contact with oils and grease with the plastic parts of the filter. The noticeable pressure

decrease at the filter, which is determined by the pressure gauge readings, may indicate that

the filter element needs to be replaced. With water a closed water takeoff tap, the pressure

gauge shows an input pressure in the system.

When opening a water takeoff tap with a clean filter, the pressure gauge readings will

decrease by Δp value. In the course of the filter operation time, this value will grow. The two-

fold increase of Δp is indicative of the fact that the filter is contaminated and must be cleaned.

Both filter washing or filtering element cleaning options are acceptable. Washing may be

performed in two methods:

A) – closing the filter outlet tap

– opening a washing valve and draining the sediments to the sewage. In this case, the

filtering element itself is not cleaned, only the sediments deposited on the bowl bottom are

removed.

B) – closing the water takeoff tap

– closing filter inlet and outlet taps

– opening the washing valve

– opening the filter outlet tap. Furthermore, the residual water in the

pipeline downstream the filter will partially remove the particles deposited on the filtering

element.

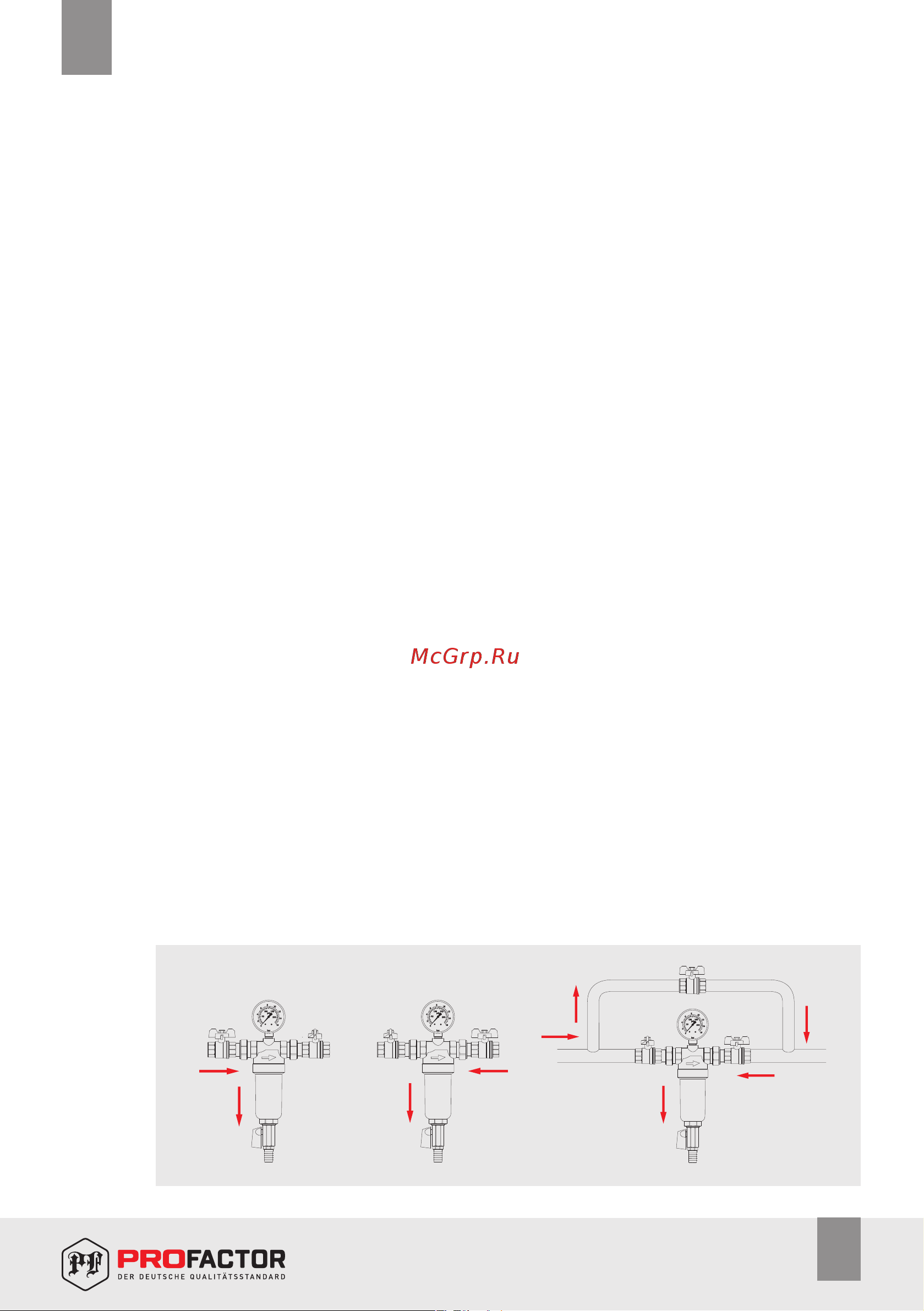

C) Backwashing of the filter (possible only if the bypass is provided):

– closing the water takeoff tap

– closing the filter inlet tap

– opening the filter outlet tap and bypass tap

– opening the washing valve. This allows cleaning the filtering element.

A)

B)

C)

The filter washing methods:

EN

Похожие устройства

- PROFACTOR 3/4" PF FS 238.20 Лайфхак

- PROFACTOR 1/2" PF FS 239G Технический паспорт

- PROFACTOR 1/2" PF FS 239G Лайфхак

- PROFACTOR 3/4" PF FS 239.20G Технический паспорт

- PROFACTOR 3/4" PF FS 239.20G Лайфхак

- PROFACTOR 1/2" PF FS 238G Технический паспорт

- PROFACTOR 1/2" PF FS 238G Лайфхак

- PROFACTOR 3/4" PF FS 238.20G Технический паспорт

- PROFACTOR 3/4" PF FS 238.20G Лайфхак

- Jeta Safety 6540 Инструкция к комплекту 6500К и 5500Р-К и фильтрам

- Jeta Safety а1, для защиты от органических газов и паров, 4 шт. 6510/4 Техническая информация по фильтру 6510

- Jeta Safety а1, для защиты от органических газов и паров, 4 шт. 6510/4 Инструкция к маскам и комплектующим Jeta Safety

- Aquanet DELIGHT 1700х780 00208600 Инструкция по подключению

- Aquanet Family Fine 170x78 95778 Gloss Finish 00292985 Инструкция по подключению

- Valtec 1 RBM 0000823 VT.389.N.06 паспорт

- Aquanet FAMILY SMART 170х78 00261053 Инструкция по подключению

- Honeywell 100 мкм FK06-3/4"AA Инструкция к Honeywell FK06-3/4AARU

- Valtec VT.192.N.07 85071 Инструкция

- DN.ru Y-образный ФСФч Ду100 Ру16 фланцевый, чугунный D260-00580 Технический паспорт

- DN.ru Y-образный ФСФч Ду125 Ру16 фланцевый, чугунный D260-00581 Технический паспорт

![PROFACTOR 3/4" PF FS 238.20 Технический паспорт онлайн [10/18] 867271](/img/pdf.png)