Graco RMLS-5 Инструкция по эксплуатации онлайн

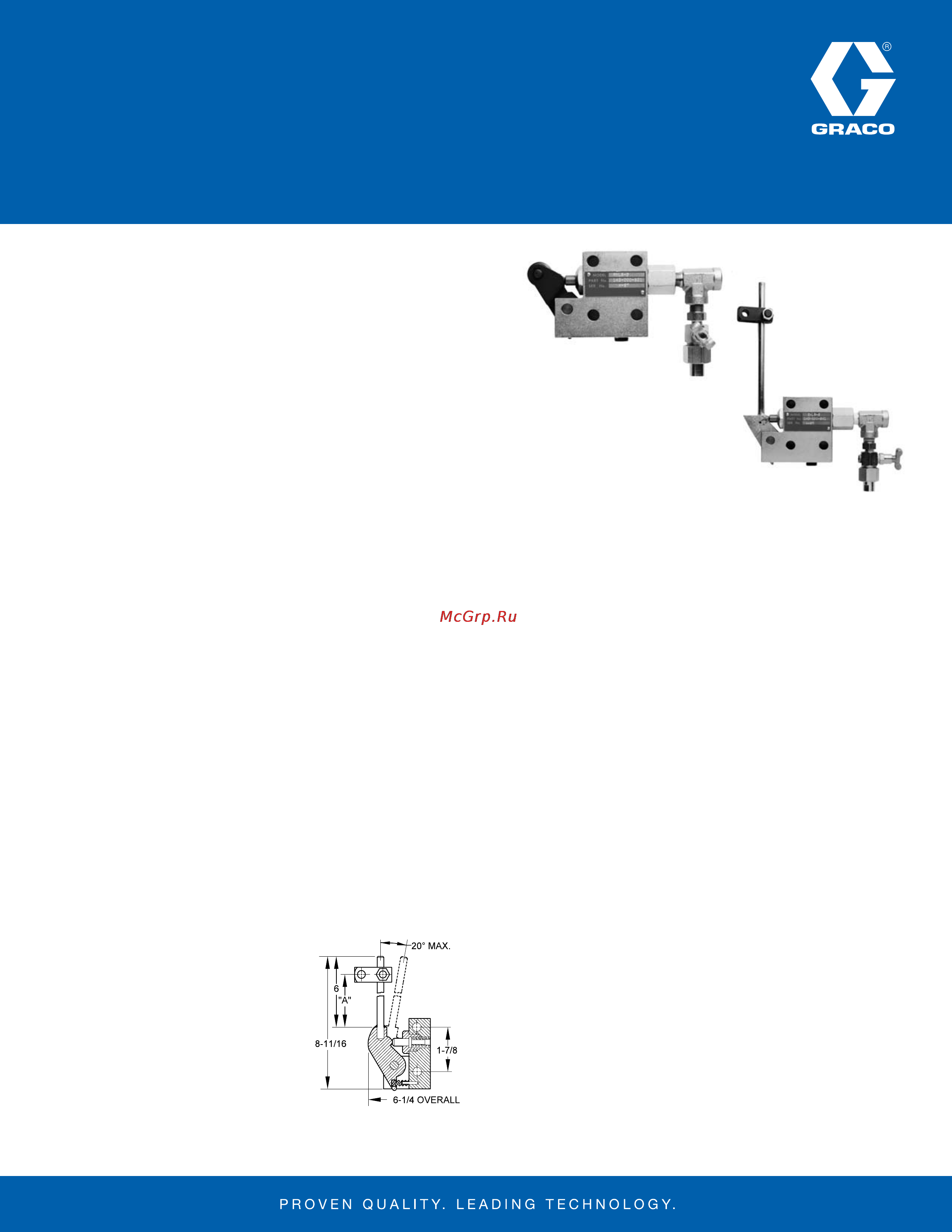

RMLS Style for Cam Roller Drive

EMLS Style for Eccentric Drive

DESCRIPTION

MLS Mechanical Lube Pumps are designed for automatic

lubrication of machinery where machine motion can be used

as the power source for the pump. The mechanical action is

transmitted directly to the pump piston, combining compactness

and simplicity. A small adjustable shot of lubricant is discharged

on each stroke of the pump. Actuation rate should be limited to 50

strokes per minute for oil and 25 strokes per minute for grease. A

mechanical force of about 75 lbs on the roller will develop 2000

psi lube pressure. Pumps will easily develop 3000 psi if required.

All MLS Pumps are equipped with a high pressure relief assembly.

Its replaceable rupture disc protects the pump and automatically

signals blockage (high pressure) in the system, should it occur.

Pumps are equipped with blow-out discs, Part No. 557435 (509-

294-000), 2050 psi). If higher or lower disc bursting pressure

is required, see Bulletin L15401 for part numbers. If desired, a

pressure gauge (sold separately) can be teed into the main outlet

(See Bulletin L15326). Also available is a high pressure blow-out

switch, Part No. 56438 (511-573-000), which can be used to

actuate a fault light or horn.

RMLS Pumps for Roller Drive

RMLS Pumps are equipped with a cam roller for cam or stop

actuation. Two sizes are available: the RMLS-5 has an output from

0.005 to 0.012 cu. in. per stroke and the RMLS-50 output ranges

from 0.020 to 0.050 cu. in. per stroke.

The stroke of the pump piston (see table in specifications) is

adjusted by varying the distance between the pump and the stop,

cam surface or trip mechanism. The tripping mechanism should

be designed with a positive lock to

prevent damage due to overtravel

of the pump piston. The slope of

the engaging cam surface should

not exceed 15 degrees.

EMLS-5 Pump for

Eccentric Drive

The EMLS-5 Pump is furnished

with a drive arm with adjustable

clevis position for powering the

pump via a connecting rod from an eccentric pin in the end of a

rotating shaft or other back-and-forth movement. Pump output

can be adjusted from 0.005 to 0.012 cu. in. per stroke.

The stroke of the pump piston (see Figure 1 and table below) is

adjusted by varying the position of the clevis on the drive arm.

So as not to exceed piston stroke limitations, the lever arm must

not be driven more than 20° or less than 10°. After determining

the exact range, attachment of permanent stops to lever arm is

suggested to prevent settings outside allowable range.

Oil reservoir assemblies are available in 5, 6, 12, 20, 24 and 40

pint sizes. Grease reservoirs have a spring-loaded follower and

are available with either metal or plastic reservoir cylinders with

capacities of 5, 6, 12 or 20 lb. Oil reservoirs of clear plastic have

a top fill snap lid and cone filter screen. A low level switch may be

ordered for any reservoir. (See Bulletin 12000 for reservoirs and

options.)

INSTALLATION & OPERATING INSTRUCTIONS

Mount pumps with their lube inlet on the top, side or bottom. Be

sure that air is purged from reservoir-to-pump line. On start-

up and after repairs, bleeding air from the pump lube chamber

is accomplished by loosening the test or air cock (item 6 on

drawings) and operating pump by hand. (Be sure to retighten

cock.)

The piston sleeve o-rings must provide a good seal. Bypass can

produce a leak at drive end of pump and reduce efficiency.

Oil reservoirs must be mounted above the pump inlet. (Spring

loaded grease reservoirs may be mounted slightly below the

pump, but only if necessary.) Grease reservoir-to-pump lines

should be 1/2” OD or 5/8” OD tubing, two feet or less in length,

with as few bends as possible. 3/8” OD tubing is satisfactory for

oil reservoir-to-pump connections.

Figure 1.

EMLS-5 Adjustment

MLS Series Mechanical Pumps

Содержание

- Description 1

- Emls 5 pump for eccentric drive 1

- Installation operating instructions 1

- Mls series mechanical pumps 1

- Rmls pumps for roller drive 1

- Rmls style for cam roller drive emls style for eccentric drive 1

- Arm travel 2 3 4 in 2 1 16 in 1 5 16 in 2

- Bill of materials 2

- Contact us today 2

- Description part no old part no 2

- Emls 5 562861 143 000 841 2

- Emls 5 see fig 1 6 in max 4 in 2 in min 2

- How to order 2

- Lube discharge 0 12 cu in 0 08 cu in 0 05 cu in 2

- Max piston stroke lube discharge 2

- Min piston stroke lube discharge 2

- Piston travel 3 8 in 9 32 in 1 5 16 in 2

- Rmls 5 0 05 cu in 3 16 in 2

- Rmls 5 0 12 cu in 3 8 in 2

- Rmls 5 562860 143 000 821 2

- Rmls 5 rmls 50 emls 5 partial 2

- Rmls 50 0 50 cu in 17 32 in 2

- Rmls 50 0 50 cu in 5 16 in 2

- Rmls 50 562858 143 000 800 2

- Rmls 50 repair kit 563901 560 000 150 2

- Rmls emls 5 repair kit 563900 560 000 140 2

- Specifications 2

- To receive product information or talk with a graco representative call 800 533 9655 or visit us online at www graco com 2

Похожие устройства

- Graco RMLS-50 Инструкция по эксплуатации

- Graco EMLS-5 Инструкция по эксплуатации

- Graco Manzel GBL 7500 Инструкция по эксплуатации

- Graco 24F531 Инструкция по эксплуатации

- Graco 24F531 Брошюра

- Graco 24F878 Инструкция по эксплуатации

- Graco 24F878 Технические характеристики

- Graco 24F947 Инструкция по эксплуатации

- Graco 24F947 Технические характеристики

- Graco 24M499 Инструкция по эксплуатации

- Graco 24M499 Технические характеристики

- Graco Python XL 1/4" Инструкция по эксплуатации

- Graco Python XL 1/4" Технические характеристики

- Graco Python XL 3/8" Инструкция по эксплуатации

- Graco Python XL 3/8" Технические характеристики

- Graco Python XL 1/2" Инструкция по эксплуатации

- Graco Python XL 1/2" Технические характеристики

- Graco Python XL 5/8" Инструкция по эксплуатации

- Graco Python XL 5/8" Технические характеристики

- Graco Python XL 3/4" Инструкция по эксплуатации