Autonics BJR3M-PDT-W-F Инструкция по эксплуатации онлайн

I N S T R U C T I O N M A N U A L

Thank you for choosing our Autonics product.

Please read the following safety considerations before use.

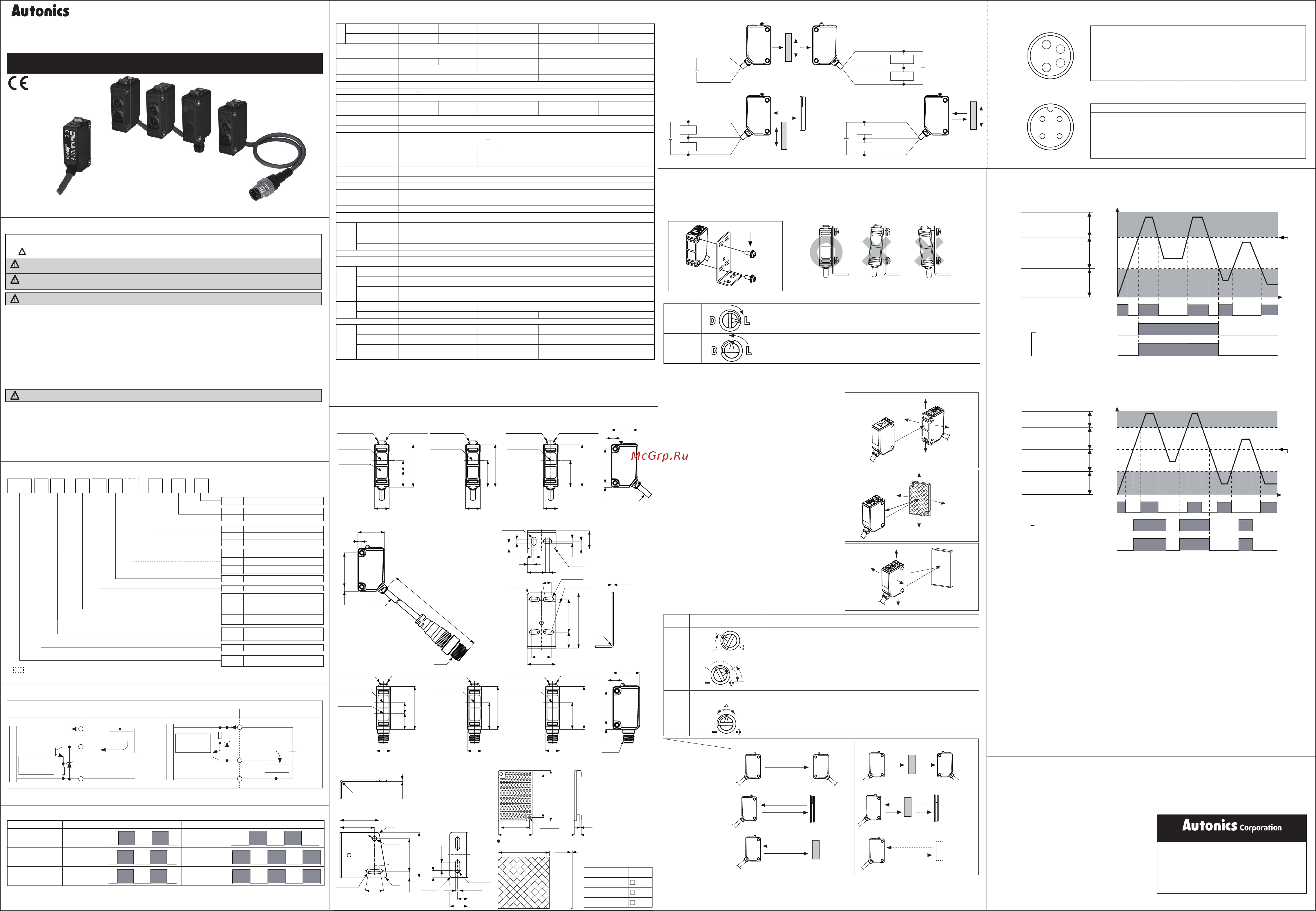

Connections for connector part

Optical axis adjustment

1. Place the emitter and the receiver facing each other and supply

the power.

2. After adjusting the position of the emitter and the receiver and

checking their stable indicating range, mount them in the middle

of the range.

3. After mounting this unit, check the operation of the sensor and

lighting of the stability indicator in both status. (none or sensing

target status)

※

If the sensing target is translucent body or smaller than Ø15mm, it

may not sense the target because light is passed.

※

Please set the sensitivity setting adjuster is executed in stable Light ON area and the reliability of environment (temperature,

supply, dust etc.) is increased after the mounting it in a stable area.

※

When adjusting sensitivity or switching operation modes, please use the Autonics adjustment screwdriver (accessory included).

Using a screwdriver with a bigger diameter than the adjuster buttons may cause errors when making adjustments.

※

It may cause breakdown when the sensitivity setting adjuster or the operation mode selection switch is turned by force.

1. Place the sensor and the refl ector (or refl ective tape) facing each

other and supply the power.

2. After adjusting the position of the sensor and refl ector (or refl ective

tape) and checking their stable indicating range, mount them in

the middle of the range. (none or sensing target status)

3. After mounting this unit, check the operation of the sensor and in

both status. (none or sensing target status)

※

Please use refl ective tape (MST Series) for where a refl ector can

not be installed.

1. Place the emitter and the receiver facing each other and supply

the power.

2. After adjusting the position of the emitter and the receiver and

checking their stable indicating range, mount them in the middle

of the range.

3. After mounting this unit, check the operation of the sensor and

lighting of the stability indicator in both status. (none or sensing

target status)

Through-beam type

Retroreflective type

Diffuse reflective type

Operation mode switching

※

For through-beam type, the switch is built-in the receiver.

Light ON

Turn the switch all the way to the right (towards L) to select Light ON operation.

Dark ON

Turn the switch all the way to the left (towards D) to select Dark ON operation.

Order Sensitivity setting Descriptions

1

(A)

From Light ON status, turn the sensitivity setting adjuster slowly to the right from

MIN sensitivity and check the position where operation indicator turns on (A).

2

(A)

(C)

(B)

From Dark ON status, turn the sensitivity setting adjuster further right and check

the position where the operation indicator turns on (B). Turn the adjuster left and

check the position where the operation indicator turns off (C).

※

If the operation indicator does not turn on at MAX sensitivity, the maximum

sensitivity setting is set at position (C).

3

Optimum sensitivity

(A) (C)

Set the adjuster at the center position between (A) and (C) for optimal sensitivity.

Also, check if the stability indicator turns off with or without the sensing target. If it

does not turn off, please review the operation mode again, as sensitivity may be

unstable.

※

1: The sensing distance is specifi ed with using the MS-2S refl ector. The distance between the sensor and the refl ector should be set

over 0.1m. When using reflective tapes, the reflectivity will vary by size of the tape. Please refer to the catalog or web site.

※

2: Non-glossy white paper 300×300mm.

※

3: Non-glossy white paper 100×100mm.

※

4: M8 connector cable is sold separately. (AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

※

5: M12 connector cable is sold separately. (AWG22, core diameter: 0.08mm, number of cores: 60, insulator out diameter: Ø1.65mm)

※

6: Cable type and cable connector type includes bracket A and connector type includes bracket B.

※

7: The weight includes packaging. The weight in parenthesis is for unit only.

※

The temperature or humidity mentioned in Environment indicates a non freezing or condensation.

Connector type

Модель A

MST-50-10

50

MST-100-5

100

MST-200-2

200

A

0.38

※

Connector pin

②

is N

.

C (Not Connected) terminal.

※

Connector pin

②

is N

.

C (Not Connected) terminal.

Connections for cable connector part

Connector pin No. Cable colors Functions Etc.

①

Brown Power Source (+V) Connector cable

(sold separately)

• CIDH4-

• CLDH4-

②

White N

.

C

③

Blue Power Source (0V)

④

Black Output

[M12 connector pin]

[M8 connector pin]

Sensitivity setting

※

The above specifi cations are subject to change and some models may be discontinued without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions (catalog, homepage).

※

The waveforms of 'Operation indicator' and 'Transistor output' are for Light ON operation.

The waveforms are reversed for Dark ON operation.

40.6

2-Ø3.8

52

60.4

2.5

8.5

34

+

-

Load

※

1

※

2

+

-

※

1

※

2

+

+

-

-

※

1

※

2

Cable connector type

12

43

3

4.5

4-R1.7

3.4

14

5

3

3.4

6

14

2-R2

8-R1.7

4-R23.7

4-10°

2-R2

42.5

25.4

12.3

15

22

(

R

)

1.2

1.2

(

R

)

R2

2-R1.7

20°

35

25.4

R2

Ø3.4

30

26.5

4.8

2-6

5.5

2-R2

2-3.4

4-R1.7

8

14

3

Ø4, 2 м

25.43.3

20

3

Ø4

M12

25.43.3

20

300

11

8

12

32

11

20

32

11

20

32

3

M8×1

25.43.3

20

1

2

4

3

Connections for cable connector part

Connector pin No. Cable colors Functions Etc.

①

Brown Power Source (+V) Connector cable

(sold separately)

• CIDH408-

• CLDH408-

②

White N

.

C

③

Blue Power Source (0V)

④

Black Output

Retrorefl ective/Diffuse refl ective type

Through-beam type

Stable light ON area

Unstable operation area

Stable light OFF area

Stability indicator

(green LED)

High

Incident

light

level

Low

ON

OFF

ON

OFF

ON

OFF

Operation

level

Operation indicator

(yellow LED)

Light ON

operation

Transistor output

Stable light ON area

Unstable light ON area

Unstable light OFF area

Stable light OFF area

Stability indicator

(green LED)

ON

OFF

High

Incident

light

level

Low

Operation

level

ON

OFF

ON

OFF

Operation indicator

(yellow LED)

Light ON

operation

Transistor output

BJR

Compact oil proof type

Photoelectric Sensor

Output type

Connection

Control output

Feature

Appearance

Power supply

Sensing type

Sensing distance unit

Sensing distance

Item

BJR 15 M T D T W P

※

This information is intended for product management of through-beam type.

(no need to refer when selecting model)

F

F Oil proof type

No mark

NPN open collector output

P PNP open collector output

No mark

Cable type

C Connector type

W Cable connector type

No mark

Integrated type

1 Emitter

2 Receiver

T Transistor output

D DC power

T Through-beam type

P

Retrorefl ective type

(built-in polarizing fi lter)

D Diffuse refl ective type

No mark

mm

M m

Number

Sensing distance

+

-

+

-

※

Install the sensor horizontally with the bracket.

Adjust Right/Left

Adjust Up/Down

Receiver

Emitter

Optic axis

Adjust Right/Left

Adjust Up/Down

Refl ector (MS-2S)

Refl ective tape

(MST series)

Adjust

Right/Left

Adjust Up/Down

Sensing target

Light ON Dark ON

Through-beam type

Emitter Receiver

Emitter Receiver

Sensing

target

Retrorefl ective type

Sensor

Refl ector (MS-2A)

Refl ective tape

(MST Series)

Refl ector (MS-2S)

Refl ective tape

(MST Series)

Sensing

target

Sensor

Diffuse refl ective type

Sensor

Sensing

target

Sensor

No sensing target

Thank you for choosing our Autonics product.

11

8

12

32

11

20

32

11

20

32

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. When connecting a DC relay or other inductive load to the output, remove surge by using diodes or varistors.

3. Use the product, 0.5 sec after supplying power.

When using separate power supply for the sensor and load, supply power to sensor first.

4. 10-30VDC power supply should be insulated and limited voltage/current or Class 2, SELV power supply device.

5. Wire as short as possible and keep away from high voltage lines or power lines, to prevent inductive noise.

6. When using switching mode power supply to supply the power, ground F.G. terminal and connect a condenser between

0V and F.G. terminal to remove noise.

7. When using sensor with the equipment which generates noise (switching regulator, inverter, servo motor, etc.), ground F.G.

terminal of the equipment.

8. This unit may be used in the following environments.

①

Indoors (in the environment condition rated in 'Specifications')

②

Altitude max. 2,000m

③

Pollution degree 3

④

Installation category II

Compact Oil Proof Type Photoelectric Sensor

BJR-F SERIES

DRW161126AD

Warning

Safety Considerations

Caution

Ordering Information

Control Output Circuit Diagram

Specifi cations

Operation mode Light ON Dark ON

Receiver operation

Received light

Interrupted light

Received light

Interrupted light

Operation indicator

(yellow LED)

ON

OFF

ON

OFF

Transistor output

ON

OFF

ON

OFF

Operation Mode

Operating Timing Diagram

For mounting

When using the refl ective type photoelectric sensors closely over three units, it may result in malfunction due to mutual

interference. When using the through-beam type photoelectric sensors closely over two units, it may result in malfunction due

to mutual interference.

When installing the product, tighten the screw with a tightening torque of 0.5N

.

m.

M3×8mm

Installation and Sensitivity Adjustment

Major Products

Cautions during Use

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse (Rate) Meters

Rotary Encoders Display Units

Connectors/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System (Fiber, CO

₂

, Nd: YAG)

Laser Welding/Cutting System

http://www.autonics.com

HEADQUARTERS:

18, Bansong-ro 513 beon-gil, Haeundae-gu, Busan, South

Korea, 48002

TEL: 82-51-519-3232

E-mail: sales@autonics.com

DRW16112 6A D

Model

NPN open

collector output

BJR15M-TDT

- -F

BJR10M-TDT

- -F

BJR3M-PDT- -F BJR1M-DDT- -F BJR100-DDT- -F

PNP open

collector output

BJR15M-TDT

-

-P-F

BJR10M-TDT

- -P-F

BJR3M-PDT- -P-F BJR1M-DDT- -P-F BJR100-DDT- -P-F

Sensing type Through-beam type

Retrorefl ective type

(built-in polarizing fi lter)

Diffuse refl ective type

Sensing distance 15m 10m 3m

※

1

1m

※

2

100mm

※

3

Sensing target Opaque material over Ø12mm

Opaque material over Ø75mm

Translucent, opaque materials

Hysteresis

-

Max. 20% at sensing distance

Response time Max. 1ms

Power supply 10-30VDC

±10% (ripple P-P: max. 10%)

Current consumption Emitter / Receiver : max. 20mA

Max. 30mA

Light source

Infrared LED

(850nm)

Red LED

(660nm)

Red LED (660nm) Red LED (660nm) Infrared LED (850nm)

Sensitivity adjustment

Sensitivity adjuster

Operation mode Light ON / Dark ON selectable by switch

Control output

NPN or PNP open collector output

• Load voltage: max. 30VDC • Load current: max. 100mA • Residual voltage - NPN: max. 1VDC , PNP: max. 2VDC

Protection circuit

Power reverse polarity

protection circuit,

output short over current

protection circuit

Power reverse polarity protection circuit,

output short over current protection circuit,

interference prevention function

Indicator Operation indicator: yellow LED, stability indicator: green LED (emitter's power indicator: red LED)

Connection Cable type, connector type, cable connector type

Insulation resistance

Over 20MΩ (at 500VDC megger)

Noise immunity ±240V the square wave noise (pulse width: 1

㎲

) by the noise simulator

Dielectric strength 1,000VAC 50/60Hz for 1 minute

Vibration 1.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Shock 500m/s

2

(approx. 50G) in each X, Y, Z direction for 3 times

Environ

ment

Ambient illu.

Sunlight: max. 11,000lx, incandescent lamp: max. 3,000lx (receiver illumination)

Ambient temp.

-25 to 60

℃

, storage: -40 to 70

℃

Ambient humi.

35 to 85%RH, storage: 35 to 85%RH

Protection structure IP67 (IEC standard), IP67F (JEM standard)

Material Case: acrylonitrile-butadiene-styrene, LED Cap: polyamide 12, sensing part: polymethyl methacrylate

Cable

Cable type

Ø4mm, 3-wire, 2m (emitter of through-beam type: Ø4mm, 2-wire, 2m)

(AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

Connector type

※4

M8 connector

Cable connector

type

※5

Ø4mm, 3-wire, 300mm (emitter of through-beam type: Ø4mm, 2-wire, 300mm), M12 connector

(AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

Acces-

sory

Common

Mounting bracket

※

6

, M3 bolt: 4,

adjustment screwdriver

Mounting bracket

※

6

, M3 bolt: 2, adjustment screwdriver

Individual

-

Refl ector (MS-2S)

-

Approval

Weight

※

7

Cable type Approx. 145g (approx. 95g)

Approx. 115g (approx. 50g)

Approx. 100g (approx. 50g)

Connector type

Approx. 65g (approx. 12g)

Approx. 75g (approx. 6g)

Approx. 60g (approx. 6g)

Cable connector

type

Approx. 105g (approx. 55g)

Approx. 95g (approx. 30g)

Approx. 80g (approx. 30g)

1. Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment, ships, vehicles,

railways, aircraft, combustion apparatus, safety

equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in fi re, personal injury, or economic loss.

2. Do not disassemble or modify the unit.

Failure to follow this instruction may result in fi re.

3. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in fi re.

4. Check ‘Connections’ before wiring.

Failure to follow this instruction may result in fi re.

1. Use the unit within the rated specifi cations.

Failure to follow this instruction may result in fi re or product damage.

2. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in fi re.

3. Do not use the unit in the place where fl ammable/explosive/corrosive gas, humidity, direct

sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in fi re or explosion.

※

Please observe all safety considerations for safe and proper product operation to avoid

hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

Warning

Failure to follow these instructions may result in serious injury or death.

Caution

Failure to follow these instructions may result in personal injury or product damage.

I N S T R U C T I O N M A N U A L

Thank you for choosing our Autonics product.

Please read the following safety considerations before use.

Connections for connector part

Optical axis adjustment

1. Place the emitter and the receiver facing each other and supply

the power.

2. After adjusting the position of the emitter and the receiver and

checking their stable indicating range, mount them in the middle

of the range.

3. After mounting this unit, check the operation of the sensor and

lighting of the stability indicator in both status. (none or sensing

target status)

※

If the sensing target is translucent body or smaller than Ø15mm, it

may not sense the target because light is passed.

※

Please set the sensitivity setting adjuster is executed in stable Light ON area and the reliability of environment (temperature,

supply, dust etc.) is increased after the mounting it in a stable area.

※

When adjusting sensitivity or switching operation modes, please use the Autonics adjustment screwdriver (accessory included).

Using a screwdriver with a bigger diameter than the adjuster buttons may cause errors when making adjustments.

※

It may cause breakdown when the sensitivity setting adjuster or the operation mode selection switch is turned by force.

1. Place the sensor and the refl ector (or refl ective tape) facing each

other and supply the power.

2. After adjusting the position of the sensor and refl ector (or refl ective

tape) and checking their stable indicating range, mount them in

the middle of the range. (none or sensing target status)

3. After mounting this unit, check the operation of the sensor and in

both status. (none or sensing target status)

※

Please use refl ective tape (MST Series) for where a refl ector can

not be installed.

1. Place the emitter and the receiver facing each other and supply

the power.

2. After adjusting the position of the emitter and the receiver and

checking their stable indicating range, mount them in the middle

of the range.

3. After mounting this unit, check the operation of the sensor and

lighting of the stability indicator in both status. (none or sensing

target status)

Through-beam type

Retroreflective type

Diffuse reflective type

Operation mode switching

※

For through-beam type, the switch is built-in the receiver.

Light ON

Turn the switch all the way to the right (towards L) to select Light ON operation.

Dark ON

Turn the switch all the way to the left (towards D) to select Dark ON operation.

Order Sensitivity setting Descriptions

1

(A)

From Light ON status, turn the sensitivity setting adjuster slowly to the right from

MIN sensitivity and check the position where operation indicator turns on (A).

2

(A)

(C)

(B)

From Dark ON status, turn the sensitivity setting adjuster further right and check

the position where the operation indicator turns on (B). Turn the adjuster left and

check the position where the operation indicator turns off (C).

※

If the operation indicator does not turn on at MAX sensitivity, the maximum

sensitivity setting is set at position (C).

3

Optimum sensitivity

(A) (C)

Set the adjuster at the center position between (A) and (C) for optimal sensitivity.

Also, check if the stability indicator turns off with or without the sensing target. If it

does not turn off, please review the operation mode again, as sensitivity may be

unstable.

※

1: The sensing distance is specifi ed with using the MS-2S refl ector. The distance between the sensor and the refl ector should be set

over 0.1m. When using reflective tapes, the reflectivity will vary by size of the tape. Please refer to the catalog or web site.

※

2: Non-glossy white paper 300×300mm.

※

3: Non-glossy white paper 100×100mm.

※

4: M8 connector cable is sold separately. (AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

※

5: M12 connector cable is sold separately. (AWG22, core diameter: 0.08mm, number of cores: 60, insulator out diameter: Ø1.65mm)

※

6: Cable type and cable connector type includes bracket A and connector type includes bracket B.

※

7: The weight includes packaging. The weight in parenthesis is for unit only.

※

The temperature or humidity mentioned in Environment indicates a non freezing or condensation.

Connector type

Модель A

MST-50-10 50

MST-100-5 100

MST-200-2 200

A

0.38

※

Connector pin

②

is N

.

C (Not Connected) terminal.

※

Connector pin

②

is N

.

C (Not Connected) terminal.

Connections for cable connector part

Connector pin No. Cable colors Functions Etc.

①

Brown Power Source (+V) Connector cable

(sold separately)

• CIDH4-

• CLDH4-

②

White N

.

C

③

Blue Power Source (0V)

④

Black Output

[M12 connector pin]

[M8 connector pin]

Sensitivity setting

※

The above specifi cations are subject to change and some models may be discontinued without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions (catalog, homepage).

※

The waveforms of 'Operation indicator' and 'Transistor output' are for Light ON operation.

The waveforms are reversed for Dark ON operation.

40.6

2-Ø3.8

52

60.4

2.5

8.5

34

+

-

Load

※

1

※

2

+

-

※

1

※

2

+

+

-

-

※

1

※

2

Cable connector type

12

43

3

4.5

4-R1.7

3.4

14

5

3

3.4

6

14

2-R2

8-R1.7

4-R23.7

4-10°

2-R2

42.5

25.4

12.3

15

22

(

R

)

1.2

1.2

(

R

)

R2

2-R1.7

20°

35

25.4

R2

Ø3.4

30

26.5

4.8

2-6

5.5

2-R2

2-3.4

4-R1.7

8

14

3

Ø4, 2 м

25.43.3

20

3

Ø4

M12

25.43.3

20

300

11

8

12

32

11

20

32

11

20

32

3

M8×1

25.43.3

20

1

2

4

3

Connections for cable connector part

Connector pin No. Cable colors Functions Etc.

①

Brown Power Source (+V) Connector cable

(sold separately)

• CIDH408-

• CLDH408-

②

White N

.

C

③

Blue Power Source (0V)

④

Black Output

Retrorefl ective/Diffuse refl ective type

Through-beam type

Stable light ON area

Unstable operation area

Stable light OFF area

Stability indicator

(green LED)

High

Incident

light

level

Low

ON

OFF

ON

OFF

ON

OFF

Operation

level

Operation indicator

(yellow LED)

Light ON

operation

Transistor output

Stable light ON area

Unstable light ON area

Unstable light OFF area

Stable light OFF area

Stability indicator

(green LED)

ON

OFF

High

Incident

light

level

Low

Operation

level

ON

OFF

ON

OFF

Operation indicator

(yellow LED)

Light ON

operation

Transistor output

BJR

Compact oil proof type

Photoelectric Sensor

Output type

Connection

Control output

Feature

Appearance

Power supply

Sensing type

Sensing distance unit

Sensing distance

Item

BJR 15 M T D T W P

※

This information is intended for product management of through-beam type.

(no need to refer when selecting model)

F

F Oil proof type

No mark

NPN open collector output

P PNP open collector output

No mark

Cable type

C Connector type

W Cable connector type

No mark

Integrated type

1 Emitter

2 Receiver

T Transistor output

D DC power

T Through-beam type

P

Retrorefl ective type

(built-in polarizing fi lter)

D Diffuse refl ective type

No mark

mm

M m

Number

Sensing distance

+

-

+

-

※

Install the sensor horizontally with the bracket.

Adjust Right/Left

Adjust Up/Down

Receiver

Emitter

Optic axis

Adjust Right/Left

Adjust Up/Down

Refl ector (MS-2S)

Refl ective tape

(MST series)

Adjust

Right/Left

Adjust Up/Down

Sensing target

Light ON Dark ON

Through-beam type

Emitter Receiver

Emitter Receiver

Sensing

target

Retrorefl ective type

Sensor

Refl ector (MS-2A)

Refl ective tape

(MST Series)

Refl ector (MS-2S)

Refl ective tape

(MST Series)

Sensing

target

Sensor

Diffuse refl ective type

Sensor

Sensing

target

Sensor

No sensing target

Thank you for choosing our Autonics product.

11

8

12

32

11

20

32

11

20

32

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. When connecting a DC relay or other inductive load to the output, remove surge by using diodes or varistors.

3. Use the product, 0.5 sec after supplying power.

When using separate power supply for the sensor and load, supply power to sensor first.

4. 10-30VDC power supply should be insulated and limited voltage/current or Class 2, SELV power supply device.

5. Wire as short as possible and keep away from high voltage lines or power lines, to prevent inductive noise.

6. When using switching mode power supply to supply the power, ground F.G. terminal and connect a condenser between

0V and F.G. terminal to remove noise.

7. When using sensor with the equipment which generates noise (switching regulator, inverter, servo motor, etc.), ground F.G.

terminal of the equipment.

8. This unit may be used in the following environments.

①

Indoors (in the environment condition rated in 'Specifications')

②

Altitude max. 2,000m

③

Pollution degree 3

④

Installation category II

Compact Oil Proof Type Photoelectric Sensor

BJR-F SERIES

DRW161126AD

Warning

Safety Considerations

Caution

Ordering Information

Control Output Circuit Diagram

Specifi cations

Operation mode Light ON Dark ON

Receiver operation

Received light

Interrupted light

Received light

Interrupted light

Operation indicator

(yellow LED)

ON

OFF

ON

OFF

Transistor output

ON

OFF

ON

OFF

Operation Mode

Operating Timing Diagram

For mounting

When using the refl ective type photoelectric sensors closely over three units, it may result in malfunction due to mutual

interference. When using the through-beam type photoelectric sensors closely over two units, it may result in malfunction due

to mutual interference.

When installing the product, tighten the screw with a tightening torque of 0.5N

.

m.

M3×8mm

Installation and Sensitivity Adjustment

Major Products

Cautions during Use

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse (Rate) Meters

Rotary Encoders Display Units

Connectors/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System (Fiber, CO

₂

, Nd: YAG)

Laser Welding/Cutting System

http://www.autonics.com

HEADQUARTERS:

18, Bansong-ro 513 beon-gil, Haeundae-gu, Busan, South

Korea, 48002

TEL: 82-51-519-3232

E-mail: sales@autonics.com

DRW16112 6A D

Model

NPN open

collector output

BJR15M-TDT

- -F

BJR10M-TDT

- -F

BJR3M-PDT- -F BJR1M-DDT- -F BJR100-DDT- -F

PNP open

collector output

BJR15M-TDT

-

-P-F

BJR10M-TDT

- -P-F

BJR3M-PDT- -P-F BJR1M-DDT- -P-F BJR100-DDT- -P-F

Sensing type Through-beam type

Retrorefl ective type

(built-in polarizing fi lter)

Diffuse refl ective type

Sensing distance 15m 10m 3m

※

1

1m

※

2

100mm

※

3

Sensing target Opaque material over Ø12mm

Opaque material over Ø75mm

Translucent, opaque materials

Hysteresis

-

Max. 20% at sensing distance

Response time Max. 1ms

Power supply 10-30VDC

±10% (ripple P-P: max. 10%)

Current consumption Emitter / Receiver : max. 20mA

Max. 30mA

Light source

Infrared LED

(850nm)

Red LED

(660nm)

Red LED (660nm) Red LED (660nm) Infrared LED (850nm)

Sensitivity adjustment

Sensitivity adjuster

Operation mode Light ON / Dark ON selectable by switch

Control output

NPN or PNP open collector output

• Load voltage: max. 30VDC • Load current: max. 100mA • Residual voltage - NPN: max. 1VDC , PNP: max. 2VDC

Protection circuit

Power reverse polarity

protection circuit,

output short over current

protection circuit

Power reverse polarity protection circuit,

output short over current protection circuit,

interference prevention function

Indicator Operation indicator: yellow LED, stability indicator: green LED (emitter's power indicator: red LED)

Connection Cable type, connector type, cable connector type

Insulation resistance

Over 20MΩ (at 500VDC megger)

Noise immunity ±240V the square wave noise (pulse width: 1

㎲

) by the noise simulator

Dielectric strength 1,000VAC 50/60Hz for 1 minute

Vibration 1.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Shock 500m/s

2

(approx. 50G) in each X, Y, Z direction for 3 times

Environ

ment

Ambient illu.

Sunlight: max. 11,000lx, incandescent lamp: max. 3,000lx (receiver illumination)

Ambient temp.

-25 to 60

℃

, storage: -40 to 70

℃

Ambient humi.

35 to 85%RH, storage: 35 to 85%RH

Protection structure IP67 (IEC standard), IP67F (JEM standard)

Material Case: acrylonitrile-butadiene-styrene, LED Cap: polyamide 12, sensing part: polymethyl methacrylate

Cable

Cable type

Ø4mm, 3-wire, 2m (emitter of through-beam type: Ø4mm, 2-wire, 2m)

(AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

Connector type

※4

M8 connector

Cable connector

type

※5

Ø4mm, 3-wire, 300mm (emitter of through-beam type: Ø4mm, 2-wire, 300mm), M12 connector

(AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

Acces-

sory

Common

Mounting bracket

※

6

, M3 bolt: 4,

adjustment screwdriver

Mounting bracket

※

6

, M3 bolt: 2, adjustment screwdriver

Individual

-

Refl ector (MS-2S)

-

Approval

Weight

※

7

Cable type Approx. 145g (approx. 95g)

Approx. 115g (approx. 50g)

Approx. 100g (approx. 50g)

Connector type

Approx. 65g (approx. 12g)

Approx. 75g (approx. 6g)

Approx. 60g (approx. 6g)

Cable connector

type

Approx. 105g (approx. 55g)

Approx. 95g (approx. 30g)

Approx. 80g (approx. 30g)

1. Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment, ships, vehicles,

railways, aircraft, combustion apparatus, safety

equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in fi re, personal injury, or economic loss.

2. Do not disassemble or modify the unit.

Failure to follow this instruction may result in fi re.

3. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in fi re.

4. Check ‘Connections’ before wiring.

Failure to follow this instruction may result in fi re.

1. Use the unit within the rated specifi cations.

Failure to follow this instruction may result in fi re or product damage.

2. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in fi re.

3. Do not use the unit in the place where fl ammable/explosive/corrosive gas, humidity, direct

sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in fi re or explosion.

※

Please observe all safety considerations for safe and proper product operation to avoid

hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

Warning

Failure to follow these instructions may result in serious injury or death.

Caution

Failure to follow these instructions may result in personal injury or product damage.

I N S T R U C T I O N M A N U A L

Thank you for choosing our Autonics product.

Please read the following safety considerations before use.

Connections for connector part

Optical axis adjustment

1. Place the emitter and the receiver facing each other and supply

the power.

2. After adjusting the position of the emitter and the receiver and

checking their stable indicating range, mount them in the middle

of the range.

3. After mounting this unit, check the operation of the sensor and

lighting of the stability indicator in both status. (none or sensing

target status)

※

If the sensing target is translucent body or smaller than Ø15mm, it

may not sense the target because light is passed.

※

Please set the sensitivity setting adjuster is executed in stable Light ON area and the reliability of environment (temperature,

supply, dust etc.) is increased after the mounting it in a stable area.

※

When adjusting sensitivity or switching operation modes, please use the Autonics adjustment screwdriver (accessory included).

Using a screwdriver with a bigger diameter than the adjuster buttons may cause errors when making adjustments.

※

It may cause breakdown when the sensitivity setting adjuster or the operation mode selection switch is turned by force.

1. Place the sensor and the refl ector (or refl ective tape) facing each

other and supply the power.

2. After adjusting the position of the sensor and refl ector (or refl ective

tape) and checking their stable indicating range, mount them in

the middle of the range. (none or sensing target status)

3. After mounting this unit, check the operation of the sensor and in

both status. (none or sensing target status)

※

Please use refl ective tape (MST Series) for where a refl ector can

not be installed.

1. Place the emitter and the receiver facing each other and supply

the power.

2. After adjusting the position of the emitter and the receiver and

checking their stable indicating range, mount them in the middle

of the range.

3. After mounting this unit, check the operation of the sensor and

lighting of the stability indicator in both status. (none or sensing

target status)

Through-beam type

Retroreflective type

Diffuse reflective type

Operation mode switching

※

For through-beam type, the switch is built-in the receiver.

Light ON

Turn the switch all the way to the right (towards L) to select Light ON operation.

Dark ON

Turn the switch all the way to the left (towards D) to select Dark ON operation.

Order Sensitivity setting Descriptions

1

(A)

From Light ON status, turn the sensitivity setting adjuster slowly to the right from

MIN sensitivity and check the position where operation indicator turns on (A).

2

(A)

(C)

(B)

From Dark ON status, turn the sensitivity setting adjuster further right and check

the position where the operation indicator turns on (B). Turn the adjuster left and

check the position where the operation indicator turns off (C).

※

If the operation indicator does not turn on at MAX sensitivity, the maximum

sensitivity setting is set at position (C).

3

Optimum sensitivity

(A) (C)

Set the adjuster at the center position between (A) and (C) for optimal sensitivity.

Also, check if the stability indicator turns off with or without the sensing target. If it

does not turn off, please review the operation mode again, as sensitivity may be

unstable.

※

1: The sensing distance is specifi ed with using the MS-2S refl ector. The distance between the sensor and the refl ector should be set

over 0.1m. When using reflective tapes, the reflectivity will vary by size of the tape. Please refer to the catalog or web site.

※

2: Non-glossy white paper 300×300mm.

※

3: Non-glossy white paper 100×100mm.

※

4: M8 connector cable is sold separately. (AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

※

5: M12 connector cable is sold separately. (AWG22, core diameter: 0.08mm, number of cores: 60, insulator out diameter: Ø1.65mm)

※

6: Cable type and cable connector type includes bracket A and connector type includes bracket B.

※

7: The weight includes packaging. The weight in parenthesis is for unit only.

※

The temperature or humidity mentioned in Environment indicates a non freezing or condensation.

Connector type

Модель A

MST-50-10 50

MST-100-5 100

MST-200-2 200

A

0.38

※

Connector pin

②

is N

.

C (Not Connected) terminal.

※

Connector pin

②

is N

.

C (Not Connected) terminal.

Connections for cable connector part

Connector pin No. Cable colors Functions Etc.

①

Brown Power Source (+V) Connector cable

(sold separately)

• CIDH4-

• CLDH4-

②

White N

.

C

③

Blue Power Source (0V)

④

Black Output

[M12 connector pin]

[M8 connector pin]

Sensitivity setting

※

The above specifi cations are subject to change and some models may be discontinued without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions (catalog, homepage).

※

The waveforms of 'Operation indicator' and 'Transistor output' are for Light ON operation.

The waveforms are reversed for Dark ON operation.

40.6

2-Ø3.8

52

60.4

2.5

8.5

34

+

-

Load

※

1

※

2

+

-

※

1

※

2

+

+

-

-

※

1

※

2

Cable connector type

12

43

3

4.5

4-R1.7

3.4

14

5

3

3.4

6

14

2-R2

8-R1.7

4-R23.7

4-10°

2-R2

42.5

25.4

12.3

15

22

(

R

)

1.2

1.2

(

R

)

R2

2-R1.7

20°

35

25.4

R2

Ø3.4

30

26.5

4.8

2-6

5.5

2-R2

2-3.4

4-R1.7

8

14

3

Ø4, 2 м

25.43.3

20

3

Ø4

M12

25.43.3

20

300

11

8

12

32

11

20

32

11

20

32

3

M8×1

25.43.3

20

1

2

4

3

Connections for cable connector part

Connector pin No. Cable colors Functions Etc.

①

Brown Power Source (+V) Connector cable

(sold separately)

• CIDH408-

• CLDH408-

②

White N

.

C

③

Blue Power Source (0V)

④

Black Output

Retrorefl ective/Diffuse refl ective type

Through-beam type

Stable light ON area

Unstable operation area

Stable light OFF area

Stability indicator

(green LED)

High

Incident

light

level

Low

ON

OFF

ON

OFF

ON

OFF

Operation

level

Operation indicator

(yellow LED)

Light ON

operation

Transistor output

Stable light ON area

Unstable light ON area

Unstable light OFF area

Stable light OFF area

Stability indicator

(green LED)

ON

OFF

High

Incident

light

level

Low

Operation

level

ON

OFF

ON

OFF

Operation indicator

(yellow LED)

Light ON

operation

Transistor output

BJR

Compact oil proof type

Photoelectric Sensor

Output type

Connection

Control output

Feature

Appearance

Power supply

Sensing type

Sensing distance unit

Sensing distance

Item

BJR 15 M T D T W P

※

This information is intended for product management of through-beam type.

(no need to refer when selecting model)

F

F Oil proof type

No mark

NPN open collector output

P PNP open collector output

No mark

Cable type

C Connector type

W Cable connector type

No mark

Integrated type

1 Emitter

2 Receiver

T Transistor output

D DC power

T Through-beam type

P

Retrorefl ective type

(built-in polarizing fi lter)

D Diffuse refl ective type

No mark

mm

M m

Number

Sensing distance

+

-

+

-

※

Install the sensor horizontally with the bracket.

Adjust Right/Left

Adjust Up/Down

Receiver

Emitter

Optic axis

Adjust Right/Left

Adjust Up/Down

Refl ector (MS-2S)

Refl ective tape

(MST series)

Adjust

Right/Left

Adjust Up/Down

Sensing target

Light ON Dark ON

Through-beam type

Emitter Receiver

Emitter Receiver

Sensing

target

Retrorefl ective type

Sensor

Refl ector (MS-2A)

Refl ective tape

(MST Series)

Refl ector (MS-2S)

Refl ective tape

(MST Series)

Sensing

target

Sensor

Diffuse refl ective type

Sensor

Sensing

target

Sensor

No sensing target

Thank you for choosing our Autonics product.

11

8

12

32

11

20

32

11

20

32

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. When connecting a DC relay or other inductive load to the output, remove surge by using diodes or varistors.

3. Use the product, 0.5 sec after supplying power.

When using separate power supply for the sensor and load, supply power to sensor first.

4. 10-30VDC power supply should be insulated and limited voltage/current or Class 2, SELV power supply device.

5. Wire as short as possible and keep away from high voltage lines or power lines, to prevent inductive noise.

6. When using switching mode power supply to supply the power, ground F.G. terminal and connect a condenser between

0V and F.G. terminal to remove noise.

7. When using sensor with the equipment which generates noise (switching regulator, inverter, servo motor, etc.), ground F.G.

terminal of the equipment.

8. This unit may be used in the following environments.

①

Indoors (in the environment condition rated in 'Specifications')

②

Altitude max. 2,000m

③

Pollution degree 3

④

Installation category II

Compact Oil Proof Type Photoelectric Sensor

BJR-F SERIES

DRW161126AD

Warning

Safety Considerations

Caution

Ordering Information

Control Output Circuit Diagram

Specifi cations

Operation mode Light ON Dark ON

Receiver operation

Received light

Interrupted light

Received light

Interrupted light

Operation indicator

(yellow LED)

ON

OFF

ON

OFF

Transistor output

ON

OFF

ON

OFF

Operation Mode

Operating Timing Diagram

For mounting

When using the refl ective type photoelectric sensors closely over three units, it may result in malfunction due to mutual

interference. When using the through-beam type photoelectric sensors closely over two units, it may result in malfunction due

to mutual interference.

When installing the product, tighten the screw with a tightening torque of 0.5N

.

m.

M3×8mm

Installation and Sensitivity Adjustment

Major Products

Cautions during Use

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse (Rate) Meters

Rotary Encoders Display Units

Connectors/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System (Fiber, CO

₂

, Nd: YAG)

Laser Welding/Cutting System

http://www.autonics.com

HEADQUARTERS:

18, Bansong-ro 513 beon-gil, Haeundae-gu, Busan, South

Korea, 48002

TEL: 82-51-519-3232

E-mail: sales@autonics.com

DRW16112 6A D

Model

NPN open

collector output

BJR15M-TDT

- -F

BJR10M-TDT

- -F

BJR3M-PDT- -F BJR1M-DDT- -F BJR100-DDT- -F

PNP open

collector output

BJR15M-TDT

-

-P-F

BJR10M-TDT

- -P-F

BJR3M-PDT- -P-F BJR1M-DDT- -P-F BJR100-DDT- -P-F

Sensing type Through-beam type

Retrorefl ective type

(built-in polarizing fi lter)

Diffuse refl ective type

Sensing distance 15m 10m 3m

※

1

1m

※

2

100mm

※

3

Sensing target Opaque material over Ø12mm

Opaque material over Ø75mm

Translucent, opaque materials

Hysteresis

-

Max. 20% at sensing distance

Response time Max. 1ms

Power supply 10-30VDC

±10% (ripple P-P: max. 10%)

Current consumption Emitter / Receiver : max. 20mA

Max. 30mA

Light source

Infrared LED

(850nm)

Red LED

(660nm)

Red LED (660nm) Red LED (660nm) Infrared LED (850nm)

Sensitivity adjustment

Sensitivity adjuster

Operation mode Light ON / Dark ON selectable by switch

Control output

NPN or PNP open collector output

• Load voltage: max. 30VDC • Load current: max. 100mA • Residual voltage - NPN: max. 1VDC , PNP: max. 2VDC

Protection circuit

Power reverse polarity

protection circuit,

output short over current

protection circuit

Power reverse polarity protection circuit,

output short over current protection circuit,

interference prevention function

Indicator Operation indicator: yellow LED, stability indicator: green LED (emitter's power indicator: red LED)

Connection Cable type, connector type, cable connector type

Insulation resistance

Over 20MΩ (at 500VDC megger)

Noise immunity ±240V the square wave noise (pulse width: 1

㎲

) by the noise simulator

Dielectric strength 1,000VAC 50/60Hz for 1 minute

Vibration 1.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Shock 500m/s

2

(approx. 50G) in each X, Y, Z direction for 3 times

Environ

ment

Ambient illu.

Sunlight: max. 11,000lx, incandescent lamp: max. 3,000lx (receiver illumination)

Ambient temp.

-25 to 60

℃

, storage: -40 to 70

℃

Ambient humi.

35 to 85%RH, storage: 35 to 85%RH

Protection structure IP67 (IEC standard), IP67F (JEM standard)

Material Case: acrylonitrile-butadiene-styrene, LED Cap: polyamide 12, sensing part: polymethyl methacrylate

Cable

Cable type

Ø4mm, 3-wire, 2m (emitter of through-beam type: Ø4mm, 2-wire, 2m)

(AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

Connector type

※4

M8 connector

Cable connector

type

※5

Ø4mm, 3-wire, 300mm (emitter of through-beam type: Ø4mm, 2-wire, 300mm), M12 connector

(AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

Acces-

sory

Common

Mounting bracket

※

6

, M3 bolt: 4,

adjustment screwdriver

Mounting bracket

※

6

, M3 bolt: 2, adjustment screwdriver

Individual

-

Refl ector (MS-2S)

-

Approval

Weight

※

7

Cable type Approx. 145g (approx. 95g)

Approx. 115g (approx. 50g)

Approx. 100g (approx. 50g)

Connector type

Approx. 65g (approx. 12g)

Approx. 75g (approx. 6g)

Approx. 60g (approx. 6g)

Cable connector

type

Approx. 105g (approx. 55g)

Approx. 95g (approx. 30g)

Approx. 80g (approx. 30g)

1. Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment, ships, vehicles,

railways, aircraft, combustion apparatus, safety

equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in fi re, personal injury, or economic loss.

2. Do not disassemble or modify the unit.

Failure to follow this instruction may result in fi re.

3. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in fi re.

4. Check ‘Connections’ before wiring.

Failure to follow this instruction may result in fi re.

1. Use the unit within the rated specifi cations.

Failure to follow this instruction may result in fi re or product damage.

2. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in fi re.

3. Do not use the unit in the place where fl ammable/explosive/corrosive gas, humidity, direct

sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in fi re or explosion.

※

Please observe all safety considerations for safe and proper product operation to avoid

hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

Warning

Failure to follow these instructions may result in serious injury or death.

Caution

Failure to follow these instructions may result in personal injury or product damage.

I N S T R U C T I O N M A N U A L

Thank you for choosing our Autonics product.

Please read the following safety considerations before use.

Connections for connector part

Optical axis adjustment

1. Place the emitter and the receiver facing each other and supply

the power.

2. After adjusting the position of the emitter and the receiver and

checking their stable indicating range, mount them in the middle

of the range.

3. After mounting this unit, check the operation of the sensor and

lighting of the stability indicator in both status. (none or sensing

target status)

※

If the sensing target is translucent body or smaller than Ø15mm, it

may not sense the target because light is passed.

※

Please set the sensitivity setting adjuster is executed in stable Light ON area and the reliability of environment (temperature,

supply, dust etc.) is increased after the mounting it in a stable area.

※

When adjusting sensitivity or switching operation modes, please use the Autonics adjustment screwdriver (accessory included).

Using a screwdriver with a bigger diameter than the adjuster buttons may cause errors when making adjustments.

※

It may cause breakdown when the sensitivity setting adjuster or the operation mode selection switch is turned by force.

1. Place the sensor and the refl ector (or refl ective tape) facing each

other and supply the power.

2. After adjusting the position of the sensor and refl ector (or refl ective

tape) and checking their stable indicating range, mount them in

the middle of the range. (none or sensing target status)

3. After mounting this unit, check the operation of the sensor and in

both status. (none or sensing target status)

※

Please use refl ective tape (MST Series) for where a refl ector can

not be installed.

1. Place the emitter and the receiver facing each other and supply

the power.

2. After adjusting the position of the emitter and the receiver and

checking their stable indicating range, mount them in the middle

of the range.

3. After mounting this unit, check the operation of the sensor and

lighting of the stability indicator in both status. (none or sensing

target status)

Through-beam type

Retroreflective type

Diffuse reflective type

Operation mode switching

※

For through-beam type, the switch is built-in the receiver.

Light ON

Turn the switch all the way to the right (towards L) to select Light ON operation.

Dark ON

Turn the switch all the way to the left (towards D) to select Dark ON operation.

Order Sensitivity setting Descriptions

1

(A)

From Light ON status, turn the sensitivity setting adjuster slowly to the right from

MIN sensitivity and check the position where operation indicator turns on (A).

2

(A)

(C)

(B)

From Dark ON status, turn the sensitivity setting adjuster further right and check

the position where the operation indicator turns on (B). Turn the adjuster left and

check the position where the operation indicator turns off (C).

※

If the operation indicator does not turn on at MAX sensitivity, the maximum

sensitivity setting is set at position (C).

3

Optimum sensitivity

(A) (C)

Set the adjuster at the center position between (A) and (C) for optimal sensitivity.

Also, check if the stability indicator turns off with or without the sensing target. If it

does not turn off, please review the operation mode again, as sensitivity may be

unstable.

※

1: The sensing distance is specifi ed with using the MS-2S refl ector. The distance between the sensor and the refl ector should be set

over 0.1m. When using reflective tapes, the reflectivity will vary by size of the tape. Please refer to the catalog or web site.

※

2: Non-glossy white paper 300×300mm.

※

3: Non-glossy white paper 100×100mm.

※

4: M8 connector cable is sold separately. (AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

※

5: M12 connector cable is sold separately. (AWG22, core diameter: 0.08mm, number of cores: 60, insulator out diameter: Ø1.65mm)

※

6: Cable type and cable connector type includes bracket A and connector type includes bracket B.

※

7: The weight includes packaging. The weight in parenthesis is for unit only.

※

The temperature or humidity mentioned in Environment indicates a non freezing or condensation.

Connector type

Модель A

MST-50-10 50

MST-100-5 100

MST-200-2 200

A

0.38

※

Connector pin

②

is N

.

C (Not Connected) terminal.

※

Connector pin

②

is N

.

C (Not Connected) terminal.

Connections for cable connector part

Connector pin No. Cable colors Functions Etc.

①

Brown Power Source (+V) Connector cable

(sold separately)

• CIDH4-

• CLDH4-

②

White N

.

C

③

Blue Power Source (0V)

④

Black Output

[M12 connector pin]

[M8 connector pin]

Sensitivity setting

※

The above specifi cations are subject to change and some models may be discontinued without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions (catalog, homepage).

※

The waveforms of 'Operation indicator' and 'Transistor output' are for Light ON operation.

The waveforms are reversed for Dark ON operation.

40.6

2-Ø3.8

52

60.4

2.5

8.5

34

+

-

Load

※

1

※

2

+

-

※

1

※

2

+

+

-

-

※

1

※

2

Cable connector type

12

43

3

4.5

4-R1.7

3.4

14

5

3

3.4

6

14

2-R2

8-R1.7

4-R23.7

4-10°

2-R2

42.5

25.4

12.3

15

22

(

R

)

1.2

1.2

(

R

)

R2

2-R1.7

20°

35

25.4

R2

Ø3.4

30

26.5

4.8

2-6

5.5

2-R2

2-3.4

4-R1.7

8

14

3

Ø4, 2 м

25.43.3

20

3

Ø4

M12

25.43.3

20

300

11

8

12

32

11

20

32

11

20

32

3

M8×1

25.43.3

20

1

2

4

3

Connections for cable connector part

Connector pin No. Cable colors Functions Etc.

①

Brown Power Source (+V) Connector cable

(sold separately)

• CIDH408-

• CLDH408-

②

White N

.

C

③

Blue Power Source (0V)

④

Black Output

Retrorefl ective/Diffuse refl ective type

Through-beam type

Stable light ON area

Unstable operation area

Stable light OFF area

Stability indicator

(green LED)

High

Incident

light

level

Low

ON

OFF

ON

OFF

ON

OFF

Operation

level

Operation indicator

(yellow LED)

Light ON

operation

Transistor output

Stable light ON area

Unstable light ON area

Unstable light OFF area

Stable light OFF area

Stability indicator

(green LED)

ON

OFF

High

Incident

light

level

Low

Operation

level

ON

OFF

ON

OFF

Operation indicator

(yellow LED)

Light ON

operation

Transistor output

BJR

Compact oil proof type

Photoelectric Sensor

Output type

Connection

Control output

Feature

Appearance

Power supply

Sensing type

Sensing distance unit

Sensing distance

Item

BJR 15 M T D T W P

※

This information is intended for product management of through-beam type.

(no need to refer when selecting model)

F

F Oil proof type

No mark

NPN open collector output

P PNP open collector output

No mark

Cable type

C Connector type

W Cable connector type

No mark

Integrated type

1 Emitter

2 Receiver

T Transistor output

D DC power

T Through-beam type

P

Retrorefl ective type

(built-in polarizing fi lter)

D Diffuse refl ective type

No mark

mm

M m

Number

Sensing distance

+

-

+

-

※

Install the sensor horizontally with the bracket.

Adjust Right/Left

Adjust Up/Down

Receiver

Emitter

Optic axis

Adjust Right/Left

Adjust Up/Down

Refl ector (MS-2S)

Refl ective tape

(MST series)

Adjust

Right/Left

Adjust Up/Down

Sensing target

Light ON Dark ON

Through-beam type

Emitter Receiver

Emitter Receiver

Sensing

target

Retrorefl ective type

Sensor

Refl ector (MS-2A)

Refl ective tape

(MST Series)

Refl ector (MS-2S)

Refl ective tape

(MST Series)

Sensing

target

Sensor

Diffuse refl ective type

Sensor

Sensing

target

Sensor

No sensing target

Thank you for choosing our Autonics product.

11

8

12

32

11

20

32

11

20

32

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. When connecting a DC relay or other inductive load to the output, remove surge by using diodes or varistors.

3. Use the product, 0.5 sec after supplying power.

When using separate power supply for the sensor and load, supply power to sensor first.

4. 10-30VDC power supply should be insulated and limited voltage/current or Class 2, SELV power supply device.

5. Wire as short as possible and keep away from high voltage lines or power lines, to prevent inductive noise.

6. When using switching mode power supply to supply the power, ground F.G. terminal and connect a condenser between

0V and F.G. terminal to remove noise.

7. When using sensor with the equipment which generates noise (switching regulator, inverter, servo motor, etc.), ground F.G.

terminal of the equipment.

8. This unit may be used in the following environments.

①

Indoors (in the environment condition rated in 'Specifications')

②

Altitude max. 2,000m

③

Pollution degree 3

④

Installation category II

Compact Oil Proof Type Photoelectric Sensor

BJR-F SERIES

DRW161126AD

Warning

Safety Considerations

Caution

Ordering Information

Control Output Circuit Diagram

Specifi cations

Operation mode Light ON Dark ON

Receiver operation

Received light

Interrupted light

Received light

Interrupted light

Operation indicator

(yellow LED)

ON

OFF

ON

OFF

Transistor output

ON

OFF

ON

OFF

Operation Mode

Operating Timing Diagram

For mounting

When using the refl ective type photoelectric sensors closely over three units, it may result in malfunction due to mutual

interference. When using the through-beam type photoelectric sensors closely over two units, it may result in malfunction due

to mutual interference.

When installing the product, tighten the screw with a tightening torque of 0.5N

.

m.

M3×8mm

Installation and Sensitivity Adjustment

Major Products

Cautions during Use

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse (Rate) Meters

Rotary Encoders Display Units

Connectors/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System (Fiber, CO

₂

, Nd: YAG)

Laser Welding/Cutting System

http://www.autonics.com

HEADQUARTERS:

18, Bansong-ro 513 beon-gil, Haeundae-gu, Busan, South

Korea, 48002

TEL: 82-51-519-3232

E-mail: sales@autonics.com

DRW16112 6A D

Model

NPN open

collector output

BJR15M-TDT

- -F

BJR10M-TDT

- -F

BJR3M-PDT- -F BJR1M-DDT- -F BJR100-DDT- -F

PNP open

collector output

BJR15M-TDT

-

-P-F

BJR10M-TDT

- -P-F

BJR3M-PDT- -P-F BJR1M-DDT- -P-F BJR100-DDT- -P-F

Sensing type Through-beam type

Retrorefl ective type

(built-in polarizing fi lter)

Diffuse refl ective type

Sensing distance 15m 10m 3m

※

1

1m

※

2

100mm

※

3

Sensing target Opaque material over Ø12mm

Opaque material over Ø75mm

Translucent, opaque materials

Hysteresis

-

Max. 20% at sensing distance

Response time Max. 1ms

Power supply 10-30VDC

±10% (ripple P-P: max. 10%)

Current consumption Emitter / Receiver : max. 20mA

Max. 30mA

Light source

Infrared LED

(850nm)

Red LED

(660nm)

Red LED (660nm) Red LED (660nm) Infrared LED (850nm)

Sensitivity adjustment

Sensitivity adjuster

Operation mode Light ON / Dark ON selectable by switch

Control output

NPN or PNP open collector output

• Load voltage: max. 30VDC • Load current: max. 100mA • Residual voltage - NPN: max. 1VDC , PNP: max. 2VDC

Protection circuit

Power reverse polarity

protection circuit,

output short over current

protection circuit

Power reverse polarity protection circuit,

output short over current protection circuit,

interference prevention function

Indicator Operation indicator: yellow LED, stability indicator: green LED (emitter's power indicator: red LED)

Connection Cable type, connector type, cable connector type

Insulation resistance

Over 20MΩ (at 500VDC megger)

Noise immunity ±240V the square wave noise (pulse width: 1

㎲

) by the noise simulator

Dielectric strength 1,000VAC 50/60Hz for 1 minute

Vibration 1.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Shock 500m/s

2

(approx. 50G) in each X, Y, Z direction for 3 times

Environ

ment

Ambient illu.

Sunlight: max. 11,000lx, incandescent lamp: max. 3,000lx (receiver illumination)

Ambient temp.

-25 to 60

℃

, storage: -40 to 70

℃

Ambient humi.

35 to 85%RH, storage: 35 to 85%RH

Protection structure IP67 (IEC standard), IP67F (JEM standard)

Material Case: acrylonitrile-butadiene-styrene, LED Cap: polyamide 12, sensing part: polymethyl methacrylate

Cable

Cable type

Ø4mm, 3-wire, 2m (emitter of through-beam type: Ø4mm, 2-wire, 2m)

(AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

Connector type

※4

M8 connector

Cable connector

type

※5

Ø4mm, 3-wire, 300mm (emitter of through-beam type: Ø4mm, 2-wire, 300mm), M12 connector

(AWG26, core diameter: 0.52mm, number of cores: 20, insulator out diameter: Ø1mm)

Acces-

sory

Common

Mounting bracket

※

6

, M3 bolt: 4,

adjustment screwdriver

Mounting bracket

※

6

, M3 bolt: 2, adjustment screwdriver

Individual

-

Refl ector (MS-2S)

-

Approval

Weight

※

7

Cable type Approx. 145g (approx. 95g)

Approx. 115g (approx. 50g)

Approx. 100g (approx. 50g)

Connector type

Approx. 65g (approx. 12g)

Approx. 75g (approx. 6g)

Approx. 60g (approx. 6g)

Cable connector

type

Approx. 105g (approx. 55g)

Approx. 95g (approx. 30g)

Approx. 80g (approx. 30g)

1. Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment, ships, vehicles,

railways, aircraft, combustion apparatus, safety

equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in fi re, personal injury, or economic loss.

2. Do not disassemble or modify the unit.

Failure to follow this instruction may result in fi re.

3. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in fi re.

4. Check ‘Connections’ before wiring.

Failure to follow this instruction may result in fi re.

1. Use the unit within the rated specifi cations.

Failure to follow this instruction may result in fi re or product damage.

2. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in fi re.

3. Do not use the unit in the place where fl ammable/explosive/corrosive gas, humidity, direct

sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in fi re or explosion.

※

Please observe all safety considerations for safe and proper product operation to avoid

hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

Warning

Failure to follow these instructions may result in serious injury or death.

Caution

Failure to follow these instructions may result in personal injury or product damage.

Компактный маслостойкий фотоэлектрический датчик

Серия BJR-F

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ

I N S T R U C T I O N M A N U A L

Thank you for choosing our Autonics product.

Please read the following safety considerations before use.

Connections for connector part

Optical axis adjustment

1. Place the emitter and the receiver facing each other and supply

the power.

2. After adjusting the position of the emitter and the receiver and

checking their stable indicating range, mount them in the middle

of the range.

3. After mounting this unit, check the operation of the sensor and

lighting of the stability indicator in both status. (none or sensing

target status)

※

If the sensing target is translucent body or smaller than Ø15mm, it

may not sense the target because light is passed.

※

Please set the sensitivity setting adjuster is executed in stable Light ON area and the reliability of environment (temperature,

supply, dust etc.) is increased after the mounting it in a stable area.

※

When adjusting sensitivity or switching operation modes, please use the Autonics adjustment screwdriver (accessory included).

Using a screwdriver with a bigger diameter than the adjuster buttons may cause errors when making adjustments.

※

It may cause breakdown when the sensitivity setting adjuster or the operation mode selection switch is turned by force.

1. Place the sensor and the refl ector (or refl ective tape) facing each

other and supply the power.

2. After adjusting the position of the sensor and refl ector (or refl ective

tape) and checking their stable indicating range, mount them in

the middle of the range. (none or sensing target status)

3. After mounting this unit, check the operation of the sensor and in

both status. (none or sensing target status)

※

Please use refl ective tape (MST Series) for where a refl ector can

not be installed.

1. Place the emitter and the receiver facing each other and supply

the power.

2. After adjusting the position of the emitter and the receiver and

checking their stable indicating range, mount them in the middle

of the range.

3. After mounting this unit, check the operation of the sensor and

lighting of the stability indicator in both status. (none or sensing

target status)

Through-beam type

Retroreflective type

Diffuse reflective type

Operation mode switching

※

For through-beam type, the switch is built-in the receiver.

Light ON

Turn the switch all the way to the right (towards L) to select Light ON operation.

Dark ON

Turn the switch all the way to the left (towards D) to select Dark ON operation.

Order Sensitivity setting Descriptions

1

(A)

From Light ON status, turn the sensitivity setting adjuster slowly to the right from

MIN sensitivity and check the position where operation indicator turns on (A).

2

(A)

(C)

(B)

From Dark ON status, turn the sensitivity setting adjuster further right and check

the position where the operation indicator turns on (B). Turn the adjuster left and

check the position where the operation indicator turns off (C).

※

If the operation indicator does not turn on at MAX sensitivity, the maximum

sensitivity setting is set at position (C).

3

Optimum sensitivity

(A) (C)

Set the adjuster at the center position between (A) and (C) for optimal sensitivity.

Also, check if the stability indicator turns off with or without the sensing target. If it

does not turn off, please review the operation mode again, as sensitivity may be

unstable.

※

1: The sensing distance is specifi ed with using the MS-2S refl ector. The distance between the sensor and the refl ector should be set