Graco Python 3/4" [4/56] Key points

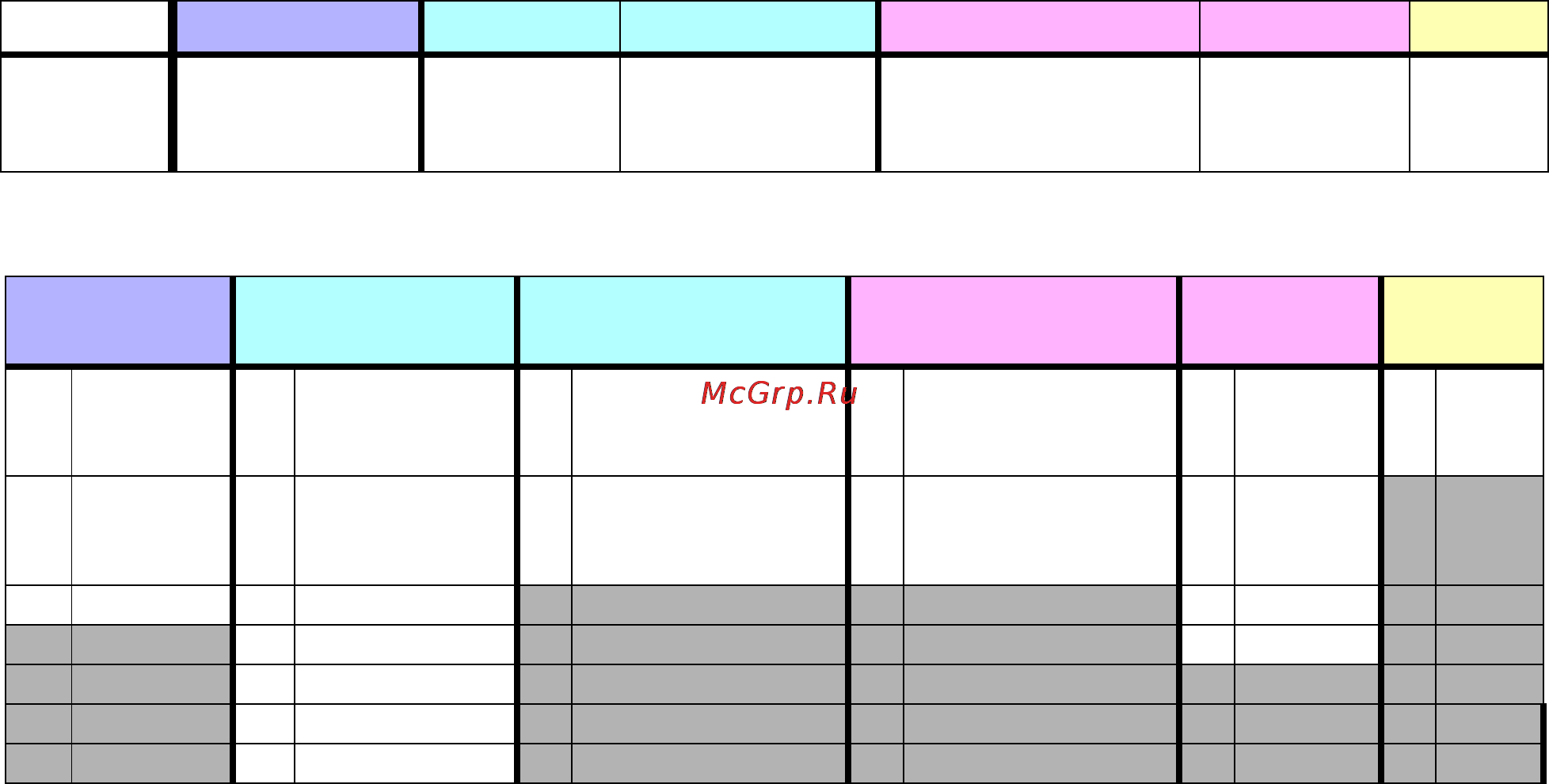

Configuration Number Matrix

4 3A3101D

Configuration Number Matrix

Check the identification plate (ID) for the 12-digit Configuration Number of your pump. Use the following matrix to

define the components of your pump.

NOTE: Not all combinations are possible.

Sample Configuration Number: PCI-125-19S-XA-0

Key Points

• Standard pressure pumps feature 1/4 in. NPT(F)

inlet and outlet connections.

• High pressure pumps feature 1/4 in. NPT(F) inlet

and HiP HF4 outlet connections.

• B32240 can be used to convert HF4 outlet connec-

tion to 1/4 in. NPT(F) for applications 10,000 psi and

under.

PCI 125 19 S X A 0

Pneumatic

Chemical

Injection

Air Motor Size Plunger Size Pressure Range Plunger Material Seal Material Qualifier

Air Motor Size Plunger Size Pressure Range Plunger Material

Seal

Material

Qualifier

125 1-1/4 inch 13 1/8” Diameter S Standard Pressure

(1/4”, 3/8”, 1/2”, 5/8”,

3/4” plungers)

C Ceramic Coated

17-4 PH Stainless

AFKM 0None

175 1-3/4 inch 19 3/16” Diameter H High Pressure

(1/8” & 3/16” plung-

ers)

X Chromex Coated

17-4 PH Stainless

B FKMETP

200 2 inch 25 1/4” Diameter CHNBR

38 3/8” Diameter D FFKM

50 1/2” Diameter

63 5/8” Diameter

75 3/4” Diameter

Содержание

- A3101d 1

- Chemical injection pump 1

- Instructions parts 1

- Contents 2

- Warnings 5 2

- Models 3

- Note see the configuration number matrix page 4 to find the plunger and air motor size for your unit 3

- Configuration number matrix 4

- Key points 4

- Warnings 5

- Component identification 7

- Numbered items in the key below correspond to the numbers in the parts lists starting on page 36 7

- Pump components 7

- Air line 8

- Fluid line 8

- Flush before using equipment 8

- Grounding 8

- Installation 8

- Required accessories 8

- Mount the pump and connect chemical supply 9

- Typical installation 9

- Connect chemical outlet 10

- Connect pneumatic supply 10

- Minimum gas pressures by fluid plunger size and outlet pressures 11

- See performance charts starting on page 44 for maximum flows at any given pressure 11

- Flush the equipment 17

- Operation 17

- Pressure relief procedure 17

- Prime the pump 18

- Calibrate chemical dosage 19

- Stroke adjustment 19

- Baseline chemical dosage settings 20

- See stroke adjustment page 19 for stroke adjust settings see performance charts starting on page 44 for maximum flows at any given pressure 20

- Maintenance 22

- Preventive maintenance schedule 22

- Storage 22

- Tighten packings 22

- Tighten threaded connections 22

- Troubleshooting 23

- Disconnect pump 24

- Repair 24

- Pump repair 25

- Reconnect fluid cylinder 26

- Remove air piston and fluid plunger assembly 27

- Air piston fluid plunger and upper cylinder reassembly 28

- Fluid plunger replacement 28

- Replace air motor seal 28

- Check valves 29

- Inlet check valve repair all models except pci xxx xxh 29

- Inlet check valve repair models pci xxx xxh only 30

- Outlet check valve repair all models except pci xxx xxh 30

- Outlet check valve repair models pci xxx xxh only 31

- Timing valve 32

- Timing valve repair 32

- Final reassembly 35

- Pci 200 13s sa 0 shown 36

- Python pneumatic pump 36

- Python pneumatic pump parts list 37

- B32069 40

- Python timing valve assembly 40

- Timing valve assembly b32069 parts list 41

- Additional kits accessories 42

- Kits and accessories 42

- A b c d e 43

- Dimensions 43

- Python pump dimensions 43

- 4 air motors pci 125 44

- 8 plunger pci 125 13 44

- Gpd lpd 44

- Outlet pressure psi mpa bar 44

- Performance charts 44

- 16 plunger pci 125 19 45

- 4 plunger pci 125 25 45

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 45

- A3101d 45 45

- Gpd lpd 45

- Inlet pressure psi 45

- Outlet pressure psi mpa bar 45

- Performance charts 45

- 2 plunger pci 125 50 46

- 3a3101d 46

- 8 plunger pci 125 38 46

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 46

- Gpd lpd 46

- Inlet pressure psi 46

- Outlet pressure psi mpa bar 46

- Performance charts 46

- 4 plunger pci 125 75 47

- 8 plunger pci 125 63 47

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 47

- A3101d 47 47

- Gpd lpd 47

- Inlet pressure psi 47

- Outlet pressure psi mpa bar 47

- Performance charts 47

- 16 plunger pci 175 19 48

- 3a3101d 48

- 4 air motors pci 175 48

- 8 plunger pci 175 13 48

- A 50 0 5 3 b 100 0 9 6 48

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 48

- Gpd lpd 48

- Inlet pressure psi 48

- Outlet pressure psi mpa bar 48

- Performance charts 48

- 4 plunger pci 175 25 49

- 8 plunger pci 175 38 49

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 49

- A3101d 49 49

- Gpd lpd 49

- Inlet pressure psi 49

- Outlet pressure psi mpa bar 49

- Performance charts 49

- 2 plunger pci 175 50 50

- 3a3101d 50

- 8 plunger pci 175 63 50

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 50

- Gpd lpd 50

- Inlet pressure psi 50

- Outlet pressure psi mpa bar 50

- Performance charts 50

- 4 plunger pci 175 75 51

- 8 plunger pci 200 13 51

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 51

- A 50 0 5 3 b 65 0 5 4 51

- A3101d 51 51

- Air motors pci 200 51

- Gpd lpd 51

- Inlet pressure psi 51

- Outlet pressure psi mpa bar 51

- Performance charts 51

- 16 plunger pci 200 19 52

- 3a3101d 52

- 4 plunger pci 200 25 52

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 52

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 52

- Gpd lpd 52

- Inlet pressure psi 52

- Outlet pressure psi mpa bar 52

- Performance charts 52

- 2 plunger pci 200 50 53

- 8 plunger pci 200 38 53

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 53

- A3101d 53 53

- Gpd lpd 53

- Inlet pressure psi 53

- Outlet pressure psi mpa bar 53

- Performance charts 53

- 3a3101d 54

- 4 plunger pci 200 75 54

- 8 plunger pci 200 63 54

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 54

- Gpd lpd 54

- Inlet pressure psi 54

- Outlet pressure psi mpa bar 54

- Performance charts 54

- Python chemical injection pump 55

- Technical data 55

- For patent information see www graco com patents 56

- For the latest information about graco products visit www graco com 56

- Graco headquarters minneapolis international offices belgium china japan korea 56

- Graco inc and subsidiaries p o box 1441 minneapolis mn 55440 1441 usa copyright 2015 graco inc all graco manufacturing locations are registered to iso 9001 www graco com revision 56

- Graco information 56

- Graco standard warranty 56

- October 2016 56

- To place an order contact your graco distributor or call to identify the nearest distributor phone 612 623 6921 or toll free 1 800 328 0211 fax 612 378 3505 56

Похожие устройства

- Graco Python 3/4" Технические характеристики

- Graco Wolverine Basic Инструкция по эксплуатации

- Graco Wolverine Advanced Simplex Инструкция по эксплуатации

- Graco Wolverine Advanced Duplex Инструкция по эксплуатации

- Graco AGP-S100 Инструкция по эксплуатации

- Graco AGP-S100 Технические характеристики

- Graco AGP-U100 Инструкция по эксплуатации

- Graco AGP-U100 Технические характеристики

- Graco AGP-P100 Инструкция по эксплуатации

- Graco AGP-P100 Технические характеристики

- Graco Therm-O-Flow 20 Инструкция по эксплуатации

- Graco Therm-O-Flow 20 Брошюра

- Graco Therm-O-Flow 200 Инструкция по эксплуатации

- Graco D200 Инструкция по эксплуатации

- Graco D200 Технические характеристики

- Graco D200s Инструкция по эксплуатации

- Graco D200s Технические характеристики

- Graco L20c Инструкция по эксплуатации

- Graco L20c Технические характеристики

- Graco S20 Инструкция по эксплуатации

![Graco Python 3/4" [4/56] Key points](/img/pdf.png)