Binks AA-4000-000-10HP Инструкция по эксплуатации онлайн

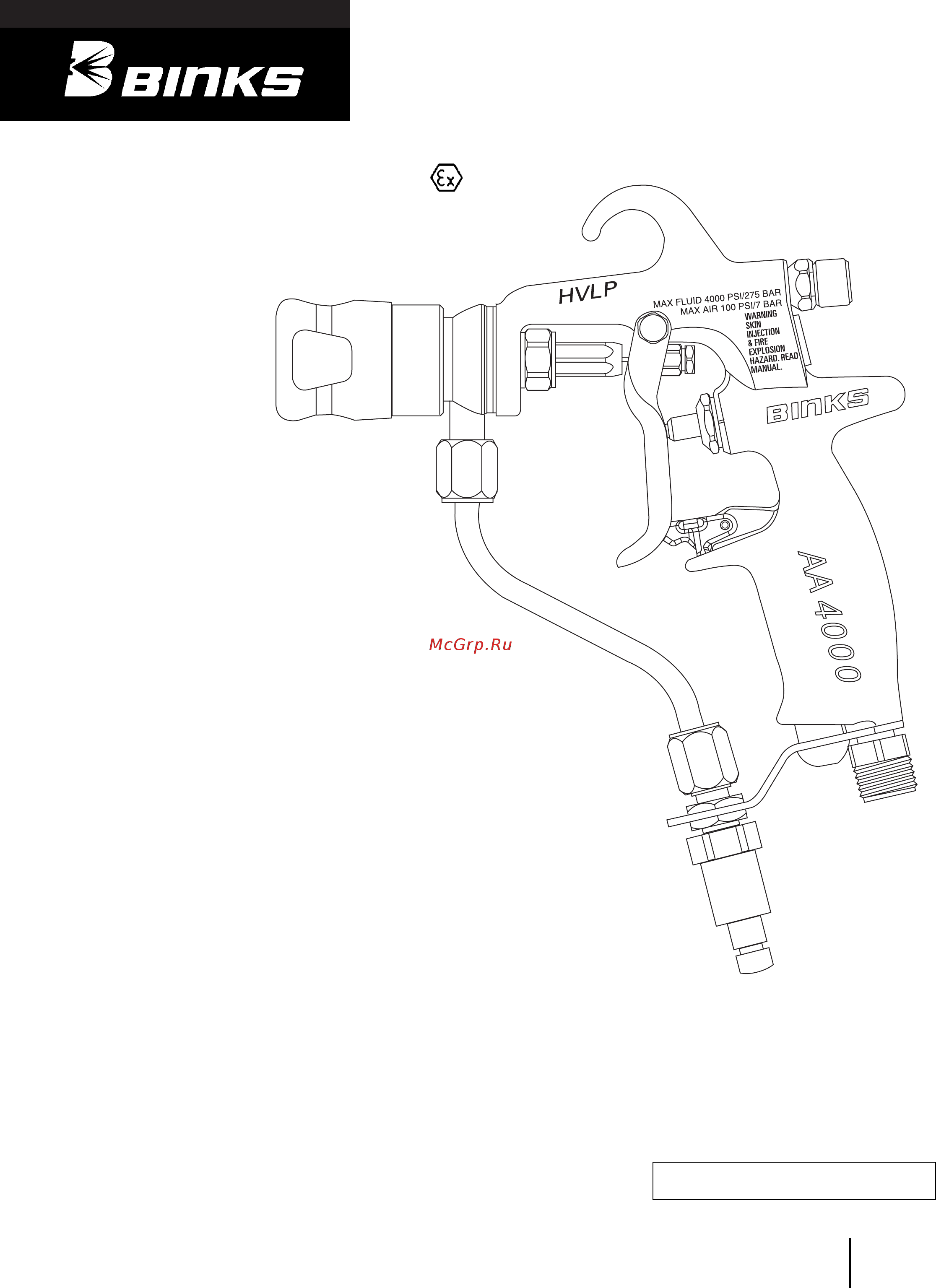

AA4000 AIR-ASSISTED

AIRLESS SPRAY GUN

The following instructions provide the

necessary information for the proper

operation and preventive maintenance

of the Binks AA4000 Air-Assisted

Airless Spray Gun. Please read and

understand all information in this

document in order to get the maximum

performance from your new AA4000

spray gun.

In the AA4000 spray gun, the paint or

other material to be sprayed is preatom-

ized and forced through the carbide tip

by the typical 1,500-3,800 psi fluid

pressure (with capabilities up to 4,000

psi/275 bar). As a result of the preatom-

izing, the final shaping air supplied by

the air cap produces an exceptionally

fine and even spray pattern. The result

of this spray pattern is an even finish

that lends itself to products that need an

exceptionally fine finish with reduced

overspray and VOC emissions.

SPECIFICATIONS:

Maximum

Fluid Pressure: 4000 psi/275 bar

Maximum

Air Pressure: 100 psi/6.8 bar

Gun Body: Forged Aluminum

Fluid Path: Stainless Steel

Fluid

Shut Off Type: Tungsten Carbide Seat standard

(UHMW Seat optional)

Fluid Inlet Size: 1/4" NPS(m) Thread

Air Inlet Size: 1/8" NPT(m) x 1/4" NPS(m)

D.M. Nipple

Gun Weight: 16-oz.

Replaces

Part Sheet

77-2776R-8

Part

Sheet

77-2776R-9

Product shown is covered by U.S. patent No. 6,276,616.

Foreign patents are issued or pending.

II 2 G X

Содержание

- Aa4000 air assisted airless spray gun 1

- Ii 2 g x 1

- In the aa4000 spray gun the paint or other material to be sprayed is preatom ized and forced through the carbide tip by the typical 1 500 3 800 psi fluid pressure with capabilities up to 4 000 psi 275 bar as a result of the preatom izing the final shaping air supplied by the air cap produces an exceptionally fine and even spray pattern the result of this spray pattern is an even finish that lends itself to products that need an exceptionally fine finish with reduced overspray and voc emissions 1

- Specifications 1

- The following instructions provide the necessary information for the proper operation and preventive maintenance of the binks aa4000 air assisted airless spray gun please read and understand all information in this document in order to get the maximum performance from your new aa4000 spray gun 1

- Caution 2

- The spray gun models listed in the following declaration of conformity may be used in some potentially explosive atmospheres only when the special conditions for safe installation and operation have been followed as expressed in this user manual part sheet these models are approved to atex regulations 94 9 ec protection level ii 2 g x suitable for use in zones 1 and 2 2

- Warning 2

- Fluid hoses 3

- Fluid tip selection 3

- Spray gun set up 3

- Typical hook up 3

- Distorted pattern 4

- Figure 3 correct pattern 4

- General troubleshooting 4

- Hour glass 4

- If cleaning or replacing the fluid tip does not dissipate the tails the spraying defect is most likely due to the material temperature and or viscosity 5 if pattern pulsation or blinking occurs check the pres sure regulators all downstream regulators and the pump these may require further adjustment or even repairs 4

- Important regulatory note 4

- Problem cause action 4

- The following procedure summarizes the steps that an operator must immediately take when the first signs of a defective spray pattern emerge 1 check the external portion of the fluid tip for material buildup if buildup has occurred secure the gun trig ger safety switch and clean the gun fluid tip with a non metal soft brush 2 if the spray pattern exhibits signs of tails at the top or bottom ends of the pattern increase the air pressure gradually until the tails disappear 3 if increasing air pressure does not dissipate the tails the fluid tip may be worn and may need to be replaced another sign of the need to replace a worn tip is a gradual decline in spraying pattern width 4

- Troubleshooting defective spray patterns 4

- Air assisted airless spray gun maintenance and cleaning 5

- Caution 5

- Cleaning 5

- Fluid tip 5

- Lubrication 5

- Spray pattern troubleshooting 5

- Warning 5

- Air valve replacement 6

- Cleaning 6

- Clearly labeled as approved for cleaning and wash off operations if the operator has any question on selecting appropriate cleaning solvents the operator should consult a supervisor or plant environmental staff 6

- Continued 6

- Engage the trigger safety 2 shut off fluid pump and disconnect its air or power supply 3 release pressure from the entire fluid system from the pump to the spray gun 6

- Parts list 6

- Refer to assembly drawing on page 7 to locate numbered items 1 engage the trigger safety 2 shut off fluid pump and disconnect its air or power supply 3 release pressure from the entire fluid system from the pump to the spray gun 4 remove tip guard assembly 1 air cap 2 and spray tip 3 remove trigger 20 by removing the trigger stud 13 and the trigger screw 12 6

- Remove the aa4000 needle packing cartridge 8 6 carefully install new aa4000 needle packing cartridge 8 7 remove fluid seat 4 and o ring 8 install new fluid seat 4 and o ring 9 reinstall trigger 20 trigger stud 13 and trigger screw 12 10 reinstall air cap 2 spray tip 3 and tip guard assembly 1 6

- Remove trigger 20 by removing the trigger stud 13 and the trigger screw 12 5 remove air valve assembly 21 6 replace air valve assembly 21 7 reinstall trigger 20 trigger stud 13 and trigger screw 12 6

- Using a rag dampened with solvent wipe the exteri or surface of the gun additionally some solvents are prohibited from being used for cleaning the opera tor must take care to use only approved cleaning sol vents for equipment cleaning these materials are 6

- Wire and ball assembly and seat replacement 6

- Aa4000 air assisted airless spray gun 7

- Aa2 optional 54 4980 thin to medium materials 8

- Aa4 standard 54 4978 medium to hvy materials 8

- Accessories 8

- Air cap application chart 8

- Application chart 8

- Binks worldwide sales and service listing www binks com 8

- Cleaning kit 8

- Fittings 8

- Fluid filters 8

- Fluid regulators 8

- Fluid seat application chart 8

- How to order the aa 4000 air assisted airless spray gun 8

- Industrial finishing 8

- Repair kit 54 4993 8

- Replacement filters 8

- Spray tip selection charts 8

- Test gauges 54 4997 8

- Warranty 8

Похожие устройства

- Binks A-75 (0811-7500-1) Инструкция по эксплуатации

- Binks A-75 (0811-7500-1) Информационный буклет

- Devilbiss Advance HD ADV-GP510-13 Инструкция по эксплуатации

- Devilbiss Advance HD ADV-GP510-13 Информационный буклет

- Binks AA4400M 0909-4400-10000 Инструкция по эксплуатации

- Binks AA4400M 0909-4400-10000 Информационный буклет

- Devilbiss DGR-501G-35 DGR-501G-35 Инструкция по эксплуатации

- Devilbiss DGR-501G-35 DGR-501G-35 Информационный буклет

- Devilbiss FLG-P5-14 Инструкция по эксплуатации

- Devilbiss FLG-P5-14 Схема подключения

- Binks AA4400M 0909-4400-10000T Инструкция по эксплуатации

- Binks AA4400M 0909-4400-10000T Информационный буклет

- Devilbiss Advance HD ADV-P513-10 Инструкция по эксплуатации

- Devilbiss Advance HD ADV-P513-10 Информационный буклет

- Devilbiss Advance HD ADV-P513-10 Схема заказа запчастей

- Devilbiss Advance HD ADV-P513-10 Схема подключения

- Devilbiss Advance HD ADV-S430-14 Инструкция по эксплуатации

- Devilbiss Advance HD ADV-S430-14 Информационный буклет

- Devilbiss Advance HD ADV-G470-28 Инструкция по эксплуатации

- Devilbiss Advance HD ADV-G470-28 Информационный буклет