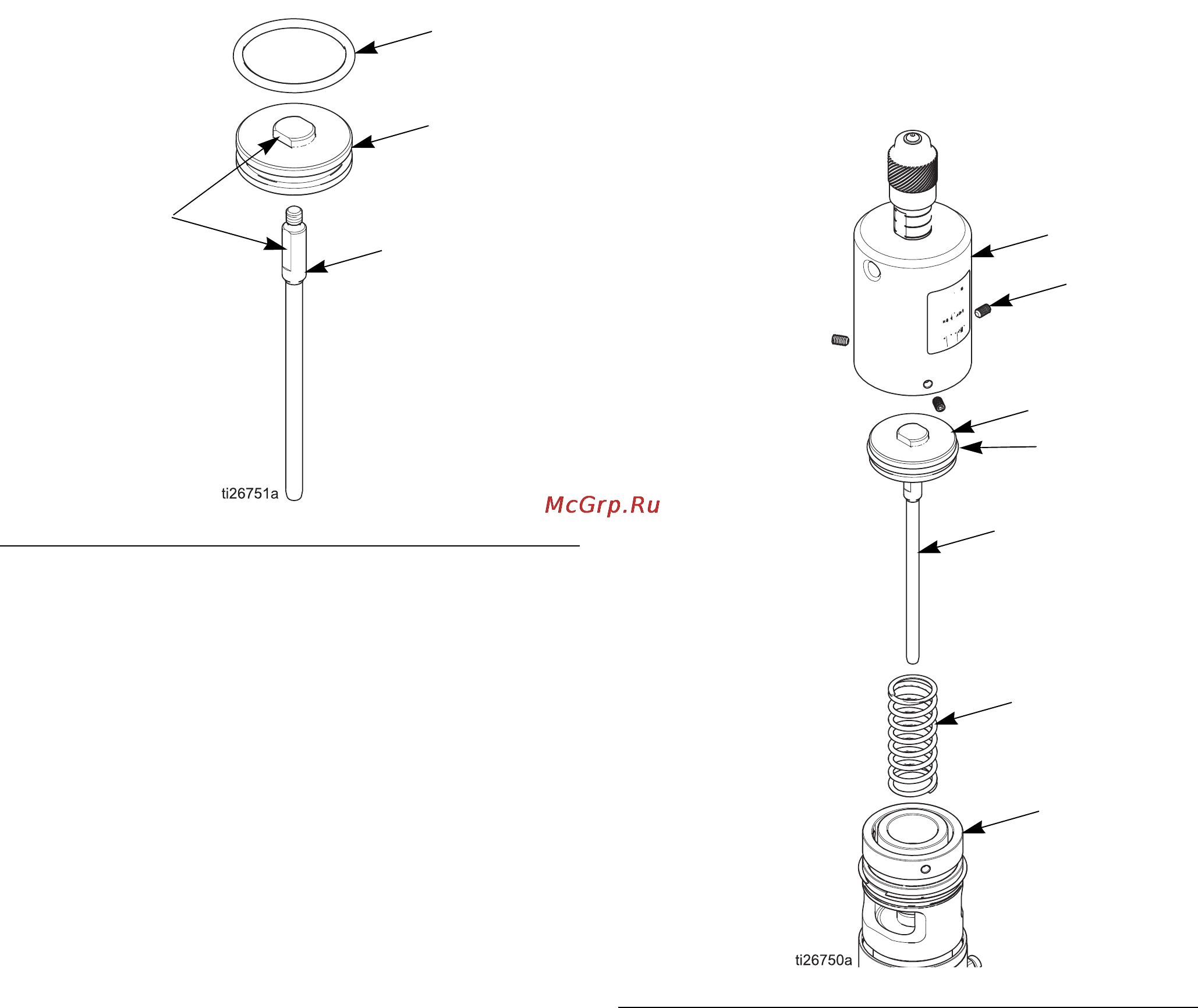

Graco Python 1/8" [28/56] Air piston fluid plunger and upper cylinder reassembly

Repair

28 3A3101D

Replace Air Motor Seal

1. Remove the air piston o-ring (7) with a plastic pick

from the air piston (6), taking great care not to

scratch any of the groove surfaces on the piston.

2. Clean any debris or buildup from the piston (6) and

plunger (5) assembly, as well as the air piston cylin-

der (8) and return spring (4).

3. Apply a liberal amount of assembly grease to the

new air piston o-ring (7), and slide it over the piston

(6) and into the groove.

Fluid Plunger Replacement

1. Use the wrench flats (see FIG. 14) located on the

piston (6) and plunger (5) to loosen and remove the

plunger from the piston.

2. Clean the dried thread locker from the internal

threads of the piston (6) as much as possible.

3. Apply a thin bead of high strength thread locker to

the external threads of the new plunger (5).

4. Install the new plunger and tighten to 75 in-lbs

(8.5 N•m).

5. Allow thread locker to dry for 60 minutes before

operating the pump.

Air Piston, Fluid Plunger, and Upper

Cylinder Reassembly

1. Ensure that all parts are cleaned before reassem-

bly.

2. Apply a thin coat of grease to the inside of the air

piston cylinder (8) and piston o-ring (7), and insert

the piston (6) and plunger (5) assembly.

3. Apply a light coat of assembly grease to the end of

the plunger (5), making certain the tip is fully coated.

4. Place the return spring (4) inside the piston stop (2).

5. Reconnect the air piston cylinder (8) to the air motor

housing (1). Carefully guide the fluid plunger (5) into

the packing nut (16) and through the packing as the

air piston cylinder is brought closer to the air motor

housing. Light pressure is required to keep the air

piston cylinder in place. Ensure the cylinder (8) is

FIG. 14 Air piston and fluid plunger

Wrench Flats

7

6

5

FIG. 15 Reassemble air piston

8

10

6

5

4

1

7

Содержание

- A3101d 1

- Chemical injection pump 1

- Instructions parts 1

- Contents 2

- Warnings 5 2

- Models 3

- Note see the configuration number matrix page 4 to find the plunger and air motor size for your unit 3

- Configuration number matrix 4

- Key points 4

- Warnings 5

- Component identification 7

- Numbered items in the key below correspond to the numbers in the parts lists starting on page 36 7

- Pump components 7

- Air line 8

- Fluid line 8

- Flush before using equipment 8

- Grounding 8

- Installation 8

- Required accessories 8

- Mount the pump and connect chemical supply 9

- Typical installation 9

- Connect chemical outlet 10

- Connect pneumatic supply 10

- Minimum gas pressures by fluid plunger size and outlet pressures 11

- See performance charts starting on page 44 for maximum flows at any given pressure 11

- Flush the equipment 17

- Operation 17

- Pressure relief procedure 17

- Prime the pump 18

- Calibrate chemical dosage 19

- Stroke adjustment 19

- Baseline chemical dosage settings 20

- See stroke adjustment page 19 for stroke adjust settings see performance charts starting on page 44 for maximum flows at any given pressure 20

- Maintenance 22

- Preventive maintenance schedule 22

- Storage 22

- Tighten packings 22

- Tighten threaded connections 22

- Troubleshooting 23

- Disconnect pump 24

- Repair 24

- Pump repair 25

- Reconnect fluid cylinder 26

- Remove air piston and fluid plunger assembly 27

- Air piston fluid plunger and upper cylinder reassembly 28

- Fluid plunger replacement 28

- Replace air motor seal 28

- Check valves 29

- Inlet check valve repair all models except pci xxx xxh 29

- Inlet check valve repair models pci xxx xxh only 30

- Outlet check valve repair all models except pci xxx xxh 30

- Outlet check valve repair models pci xxx xxh only 31

- Timing valve 32

- Timing valve repair 32

- Final reassembly 35

- Pci 200 13s sa 0 shown 36

- Python pneumatic pump 36

- Python pneumatic pump parts list 37

- B32069 40

- Python timing valve assembly 40

- Timing valve assembly b32069 parts list 41

- Additional kits accessories 42

- Kits and accessories 42

- A b c d e 43

- Dimensions 43

- Python pump dimensions 43

- 4 air motors pci 125 44

- 8 plunger pci 125 13 44

- Gpd lpd 44

- Outlet pressure psi mpa bar 44

- Performance charts 44

- 16 plunger pci 125 19 45

- 4 plunger pci 125 25 45

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 45

- A3101d 45 45

- Gpd lpd 45

- Inlet pressure psi 45

- Outlet pressure psi mpa bar 45

- Performance charts 45

- 2 plunger pci 125 50 46

- 3a3101d 46

- 8 plunger pci 125 38 46

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 46

- Gpd lpd 46

- Inlet pressure psi 46

- Outlet pressure psi mpa bar 46

- Performance charts 46

- 4 plunger pci 125 75 47

- 8 plunger pci 125 63 47

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 47

- A3101d 47 47

- Gpd lpd 47

- Inlet pressure psi 47

- Outlet pressure psi mpa bar 47

- Performance charts 47

- 16 plunger pci 175 19 48

- 3a3101d 48

- 4 air motors pci 175 48

- 8 plunger pci 175 13 48

- A 50 0 5 3 b 100 0 9 6 48

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 48

- Gpd lpd 48

- Inlet pressure psi 48

- Outlet pressure psi mpa bar 48

- Performance charts 48

- 4 plunger pci 175 25 49

- 8 plunger pci 175 38 49

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 49

- A3101d 49 49

- Gpd lpd 49

- Inlet pressure psi 49

- Outlet pressure psi mpa bar 49

- Performance charts 49

- 2 plunger pci 175 50 50

- 3a3101d 50

- 8 plunger pci 175 63 50

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 50

- Gpd lpd 50

- Inlet pressure psi 50

- Outlet pressure psi mpa bar 50

- Performance charts 50

- 4 plunger pci 175 75 51

- 8 plunger pci 200 13 51

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 51

- A 50 0 5 3 b 65 0 5 4 51

- A3101d 51 51

- Air motors pci 200 51

- Gpd lpd 51

- Inlet pressure psi 51

- Outlet pressure psi mpa bar 51

- Performance charts 51

- 16 plunger pci 200 19 52

- 3a3101d 52

- 4 plunger pci 200 25 52

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 52

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 52

- Gpd lpd 52

- Inlet pressure psi 52

- Outlet pressure psi mpa bar 52

- Performance charts 52

- 2 plunger pci 200 50 53

- 8 plunger pci 200 38 53

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 53

- A3101d 53 53

- Gpd lpd 53

- Inlet pressure psi 53

- Outlet pressure psi mpa bar 53

- Performance charts 53

- 3a3101d 54

- 4 plunger pci 200 75 54

- 8 plunger pci 200 63 54

- A 50 0 5 3 b 100 0 9 6 c 150 1 3 10 d 200 1 8 13 54

- Gpd lpd 54

- Inlet pressure psi 54

- Outlet pressure psi mpa bar 54

- Performance charts 54

- Python chemical injection pump 55

- Technical data 55

- For patent information see www graco com patents 56

- For the latest information about graco products visit www graco com 56

- Graco headquarters minneapolis international offices belgium china japan korea 56

- Graco inc and subsidiaries p o box 1441 minneapolis mn 55440 1441 usa copyright 2015 graco inc all graco manufacturing locations are registered to iso 9001 www graco com revision 56

- Graco information 56

- Graco standard warranty 56

- October 2016 56

- To place an order contact your graco distributor or call to identify the nearest distributor phone 612 623 6921 or toll free 1 800 328 0211 fax 612 378 3505 56

Похожие устройства

- Graco Python 1/8" Брошюра

- Graco Python 3/16" Инструкция по эксплуатации

- Graco Python 3/16" Технические характеристики

- Graco Python 1/4" Инструкция по эксплуатации

- Graco Python 1/4" Технические характеристики

- Graco Python 3/8" Инструкция по эксплуатации

- Graco Python 3/8" Технические характеристики

- Graco Python 1/2" Инструкция по эксплуатации

- Graco Python 1/2" Технические характеристики

- Graco Python 5/8" Инструкция по эксплуатации

- Graco Python 5/8" Технические характеристики

- Graco Python 3/4" Инструкция по эксплуатации

- Graco Python 3/4" Технические характеристики

- Graco Wolverine Basic Инструкция по эксплуатации

- Graco Wolverine Advanced Simplex Инструкция по эксплуатации

- Graco Wolverine Advanced Duplex Инструкция по эксплуатации

- Graco AGP-S100 Инструкция по эксплуатации

- Graco AGP-S100 Технические характеристики

- Graco AGP-U100 Инструкция по эксплуатации

- Graco AGP-U100 Технические характеристики

![Graco Python 1/8" [28/56] Air piston fluid plunger and upper cylinder reassembly](/img/pdf.png)